Understanding Wax Trees: The Core of Lost Wax Casting

What Is a Wax Tree / Casting Tree?

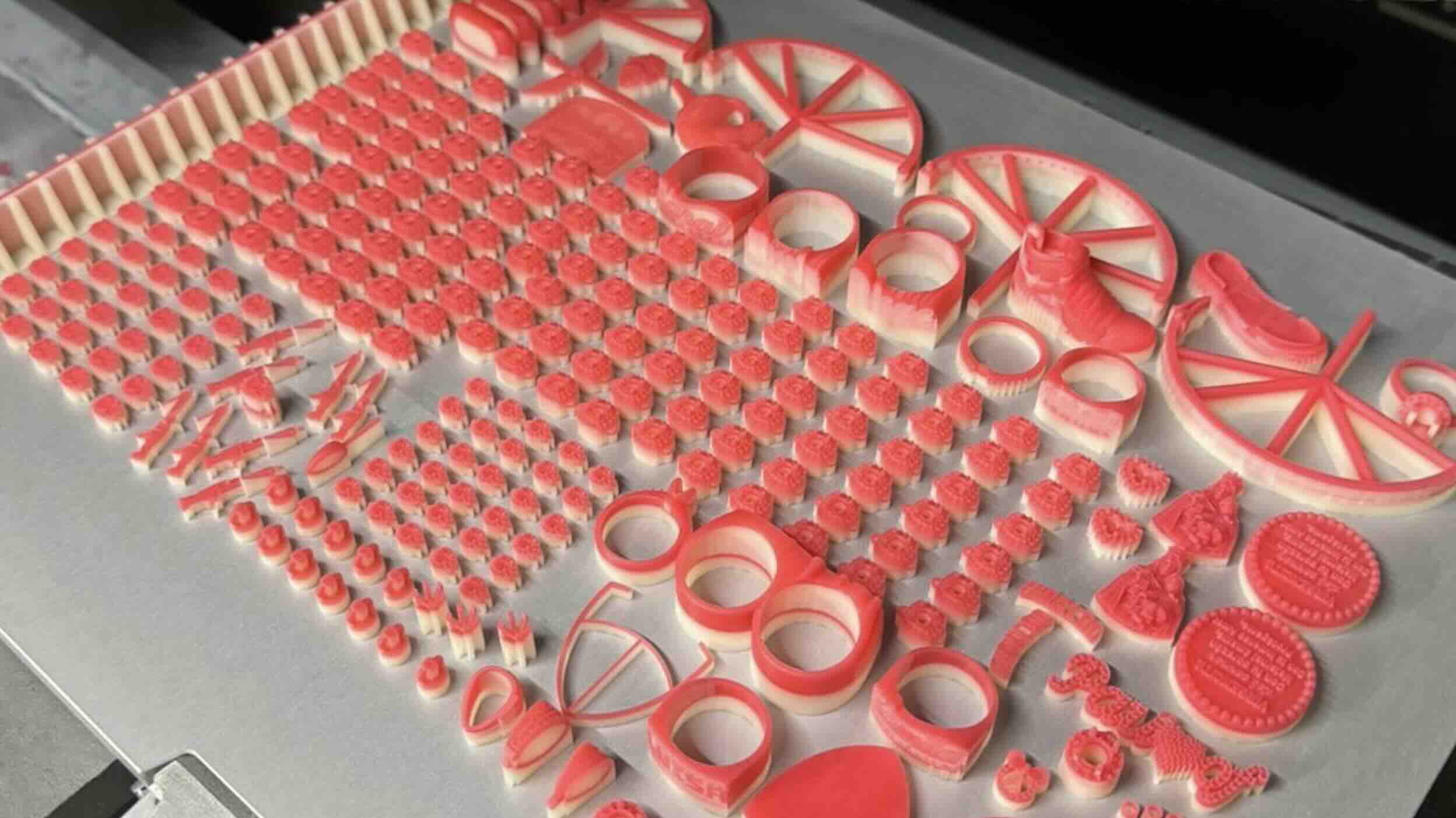

Structure and Design Principles of the Wax Tree

-

Main Sprue (Trunk): The main channel for molten metal, requiring sufficient diameter and strength to endure high temperatures (for example, gold melts at ~1064 °C).

-

Branch Sprues (Branches): Secondary flow paths connecting the trunk to each wax model. Their number, angle, and thickness influence how evenly the metal fills each mold.

-

Wax Patterns (Fruits): The jewelry prototypes at each branch tip, made from red wax or specialized casting waxsuitable for high-precision applications.

How Wax Trees Are Made

Today, most jewelry factories still rely on the traditional manual wax tree assembly method, primarily because it requires relatively low technical complexity and offers flexibility in daily production. Skilled workers with basic casting experience can produce casting trees that meet standard requirements without the need for advanced equipment or software. As a result, this method remains widely used across jewelry manufacturing facilities, especially in small and mid-sized workshops.

The manual process, often called “wax tree planting”, involves several key steps. First, each red wax or casting wax jewelry model is inspected and trimmed to remove surface defects. Next, workers use a heated metal tool or wax pen to melt and weld the individual wax patterns onto a central sprue rod at carefully chosen angles. The structure is gradually built up branch by branch, ensuring that each connection is smooth and strong enough to handle the subsequent molding process. Finally, the completed wax tree is visually checked for symmetry, balance, and spacing between models before it is placed into the casting flask.

Key Process Standards for Wax Tree Fabrication

-

Wax Surface Quality: Each wax pattern should be smooth, bubble-free, and defect-free. Minor flaws can replicate into metal. Polishing or vapor smoothing can improve surface finish, especially for 3D printed wax parts.

-

Branch Angle: Typically between 30°–45°, balancing smooth metal flow and minimizing stress.

-

Sprue Diameter Ratio: The trunk should always be thicker than branches for proper metal distribution.

-

Structural Balance: The tree should remain symmetrical to ensure even metal flow and cooling.

-

Cleaning and Mold Preparation: Dust or oils hinder plaster adhesion. A clean, dry wax surface ensures defect-free casting.

-

Post-Processing (for 3D Printing Wax): Supports are removed, surfaces polished, and fine adjustments made for optimal precision.

Advantages of Wax Trees in Batch Jewelry Casting

-

Higher Productivity: Dozens of pieces can be cast in a single pour.

-

Lower Costs: Less metal waste, reduced manual labor, and energy savings.

-

Consistent Quality: Fixed geometry ensures uniform size and detail.

-

Improved Casting Results: Reduced air bubbles, cracks, and surface imperfections.

-

Seamless Integration with Digital Tools: Compatible with CAD modeling, 3D printing wax, and smart casting systems.