Jewelry 3D Printers with Clean Burnout Wax: Why Low-Ash Wax Matters

Introduction: Clean Burnout Is Where Casting Problems Really Begin

In jewelry investment casting, wax patterns are only the starting point—not the final determinant of success. From wax 3D printing and shell building to burnout and metal pouring, every step matters. Yet in real-world production, many casting failures don’t originate where people expect.

In theory, wax should completely melt and vaporize during burnout, leaving the plaster shell clean and uncontaminated. In reality, many jewelry manufacturers encounter frustrating issues such as:

- Wax molds look highly detailed, but cast surfaces appear rough or covered with pinholes

- Thin walls, micro-details, or internal channels fail to fill properly

- Identical wax patterns from the same batch produce inconsistent casting results

These problems are often blamed on shell materials or pouring temperatures. However, in many cases, the real issue is simpler and harder to see: the wax never burned out completely.

When wax materials contain fillers, inconsistent internal density, or unstable thermal behavior, ash and carbon residue can remain inside the shell. Once metal is poured, those residues disrupt metal flow and are permanently transferred onto the final casting.

That is why experienced manufacturers increasingly focus on one practical outcome rather than just print resolution: using a jewelry 3D printer with clean burnout wax.

1. What Does “Clean Burnout Wax” Really Mean in Jewelry Casting?

1.1 Clean Burnout Is About What’s Left Behind—Or Not

Clean burnout wax does not simply mean that wax disappears at high temperature. In professional jewelry casting, it means the wax is removed completely, consistently, and predictably, without introducing defects downstream.

A wax pattern with true clean burnout characteristics behaves in a very specific way:

- It melts evenly during the early heating stage and drains smoothly from the shell

- It vaporizes fully at higher temperatures without carbonizing

- It leaves no ash, soot, or oily residue on the shell surface

- It does not block fine channels, internal cavities, or delicate geometry

- It allows molten metal to flow freely and replicate details accurately

After burnout, the inside of a properly prepared shell should look clean and uniform, not scorched, stained, or partially blocked.

Clean burnout is not defined by a single temperature point. It is the result of wax chemistry, printed structure, internal density consistency, and the entire burnout curve working together.

1.2 Clean Burnout Wax vs. Ordinary Wax Patterns

Not all wax materials behave the same under heat, even if they print well. Many casting defects originate from underestimating how critical wax burnout behavior is.

From a material standpoint, some waxes are modified to improve rigidity or print stability. These formulations often introduce fillers or additives that do not fully decompose. During burnout, they turn into ash—and ash has nowhere to go.

From a printing standpoint, unstable wax jetting or poor droplet control can create internal density variations. These differences are invisible on the surface but become amplified during burnout:

- Some regions burn out cleanly

- Others retain residue

- Internal cavities trap contaminants

The result appears later as rough surfaces, incomplete fills, or lost detail. The real difference between clean burnout wax and ordinary wax is not whether it can burn, but whether it burns out completely under real production conditions.

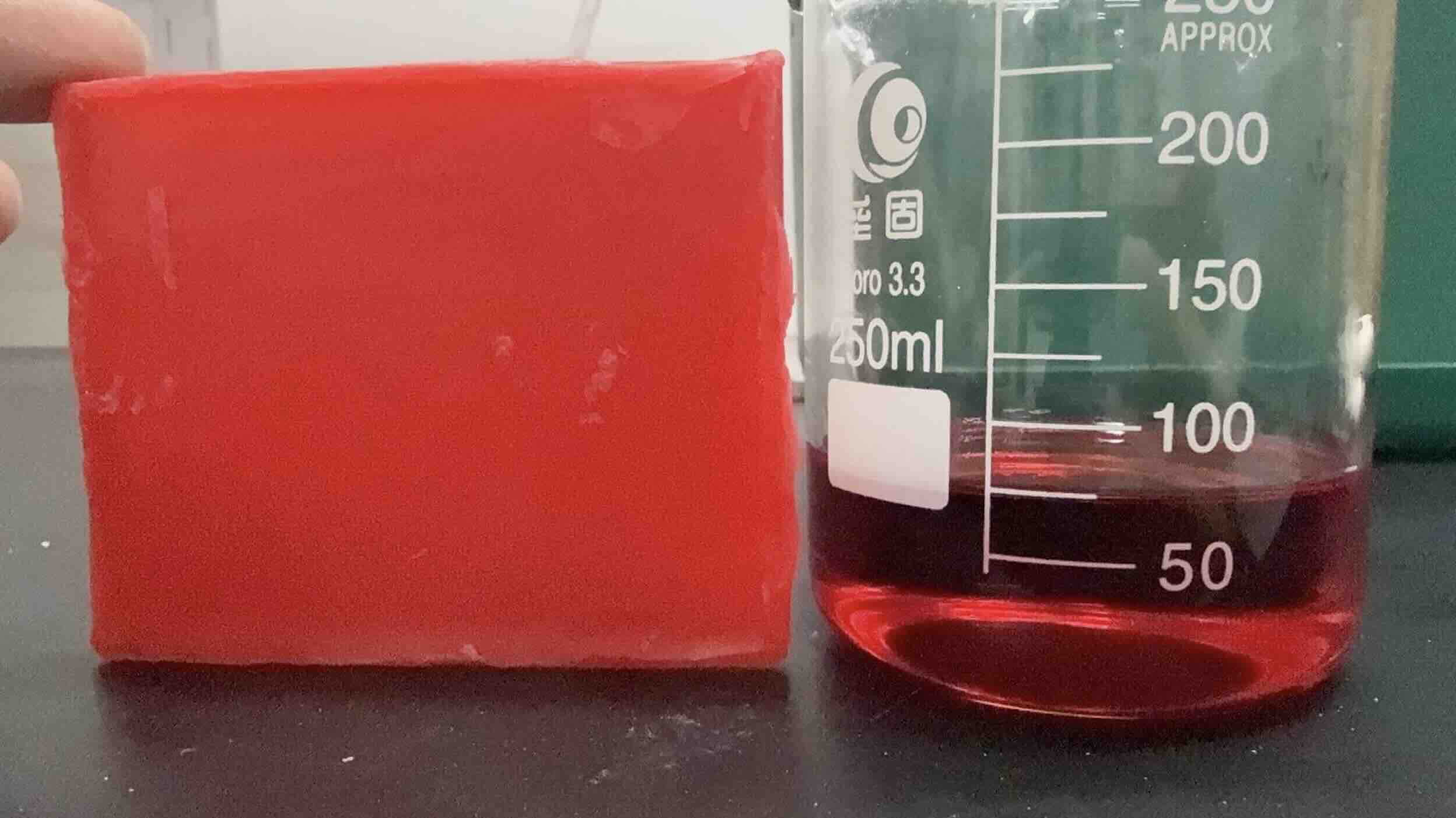

2. Why Flashforge Red Wax Achieves Ultra-Low Ash Performance

2.1 Verified Ultra-Low Ash Content

Flashforge red wax achieves an average ash content of approximately 0.008%, verified by independent third-party testing in accordance with GB/T 14235.3, the national standard for casting wax ash content.

Ash content is not just a theoretical metric. It directly determines how clean the shell interior remains after burnout.

2.2 High-Purity Wax Composition and Excellent Melt Flow

The formulation of Flashforge red wax is based primarily on high-purity wax components rather than fillers. As a result:

- The wax melts completely at around 95°C

- It flows easily out of complex geometries and dead-end structures

- Residual material is minimized before high-temperature stages begin

This flow behavior is especially important for jewelry designs with fine prongs, micro-details, and internal channels.

2.3 Clean Thermal Decomposition Without Fillers

Unlike modified waxes, Flashforge red wax contains no particulate fillers and no cross-linking components that resist decomposition.

Instead of carbonizing, the wax fully decomposes and vaporizes at elevated temperatures. Since plaster shells are typically sintered at around 700°C, well above the wax decomposition range, the burnout process has sufficient thermal margin to ensure complete removal.

3. FAQ: Clean Burnout Wax in Jewelry 3D Printing

What actually qualifies as clean burnout?

Clean burnout means no ash, no carbon residue, and no contamination that interferes with metal flow or surface reproduction.

Can all wax 3D printers achieve clean burnout?

No. Clean burnout depends on wax formulation, print consistency, and internal structure—not just printer resolution.

Does clean burnout affect stone setting accuracy?

Yes. Residue inside stone seats can cause dimensional errors and surface defects that complicate setting.

How should manufacturers verify burnout quality before mass production?

By inspecting shells after burnout, evaluating casting surfaces, and testing consistency across multiple batches.

Is wax always better than castable resin for jewelry casting?

For most fine jewelry applications, wax offers lower ash, lower thermal expansion, and more predictable burnout behavior.