Introduction to Wax Materials for Flashforge MJP 3D Printers

In jewelry manufacturing and precision casting, the importance of casting wax is often underestimated. However, industry professionals know that wax materials largely determine the upper limit of casting quality. Whether producing micro-pavé ring settings, prongs, lattice structures, lightweight geometries, gold bangles, or mass-manufactured jewelry lines, the wax used in 3D printing wax patterns plays an irreplaceable role throughout the lost-wax casting process. It directly affects dimensional accuracy, edge sharpness, surface detail, burnout cleanliness, and the final metal finish. As jewelry designs become increasingly complex and production cycles grow shorter, the stability and compatibility of wax materials have become critical to increasing factory throughput, reducing rework, and minimizing scrap rates.

Flashforge’s MJP 3d printers—including the WaxJet 400 series, WaxJet 510, and WJ530—has been adopted by a growing number of jewelry manufacturers worldwide. Beyond high precision and stable performance, the real advantage lies in its dual-material formulation: a high-resolution Flashforge wax as the model material, paired with water-soluble support wax. This system dramatically improves the manufacturability of complex designs by eliminating manual support removal and reducing the risk of damaging fine features such as pavé prongs, hollow filigree, undercuts, and ultra-lightweight structures.

Wax of MJP 3d printers

Flashforge currently offers two main categories of wax materials for its wax 3D printers: purple wax and red wax, each optimized for different machine.

Purple Wax (for WaxJet 400 & WaxJet 410)

Paired with white water-soluble support wax, this formulation offers excellent surface smoothness and fine detail resolution. Its low shrinkage and moderate strength make it ideal for lightweight or highly intricate jewelry—designer pieces, bespoke customization, micro-pavé structures, hollow designs, and complex lightweight rings.

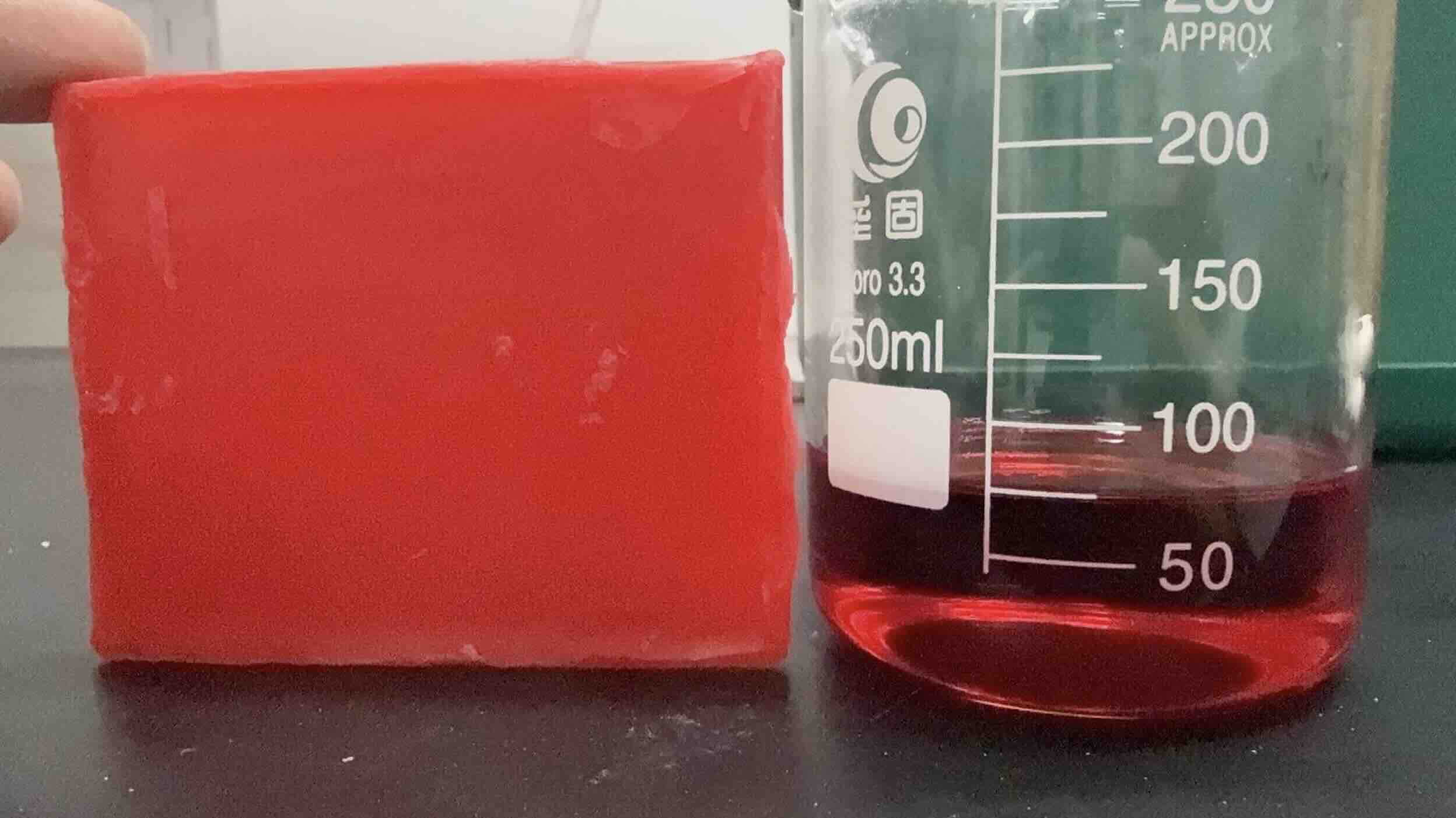

Red Wax (for WaxJet 510 & WJ530)

Designed for industrial-scale stability, the red wax offers higher strength and improved resistance to deformation during long builds. This makes it well-suited for heavier gold pieces, thick rings, bangles, and large components that require rigidity and consistent shrinkage control. Factories producing high-volume batches prefer this wax for its exceptional dimensional consistency across multiple production cycles.

Both Flashforge wax formulations share a key advantage: extremely clean burnout with minimal ash residue. This ensures no shell cracking, no contamination, and no rough surfaces on the metal casting—an essential factor for high-quality jewelry production. Their controlled linear and volumetric shrinkage also ensures the wax patterns remain stable during storage, a critical requirement for large-scale gold jewelry factories aiming for accurate weight and consistent dimensions.

Water-Soluble Support Wax

Flashforge’s white water-soluble support wax is a major strength of its 3D wax-printing system. Unlike traditional support removal—which risks breaking delicate prongs or deforming thin structures—the water-soluble wax dissolves in warm water or a solvent mix at 43°C without damaging the printed model. This allows complex internal cavities, hollow geometries, deep undercuts, and multi-layer lattice designs to be produced safely and reliably. For the jewelry industry, this means design freedom is no longer constrained by manufacturing limitations.

Why More Jewelry Factories Are Shifting to Digital Wax Printing

Many gold jewelry manufacturers are transitioning from conventional injection-wax molds to digital 3D printing wax patterns. One major reason is the stability and reliability provided by Flashforge’s wax materials. The wax can be stored long-term at 18–26°C without cracking or warping, making it suitable for continuous, industrial-scale production.

- Designers and small studios benefit from the purple wax’s ultra-high detail reproduction and safe water-soluble supports.

- Factories and mass producers favor the red wax for its strength, batch consistency, and suitability for solid gold and high-volume production lines.