3D printing application: carbon fiber composites with higher strength performance

1. Carbon fiber composites can be used in 3D printing

Carbon fiber composites are composite materials with carbon fibers embedded in matrix materials. While the matrix materials can be resin, thermoplastic, or others, the most common type is carbon fiber in thermoplastics and people often call it carbon fiber reinforced polymer. Carbon fiber is usually abbreviated to CF, so when you see those short names of PLA-CF, PETG-CF, PA-CF or Nylon-CF you'll know those are carbon fiber composites with thermoplastics as the matrix materials.

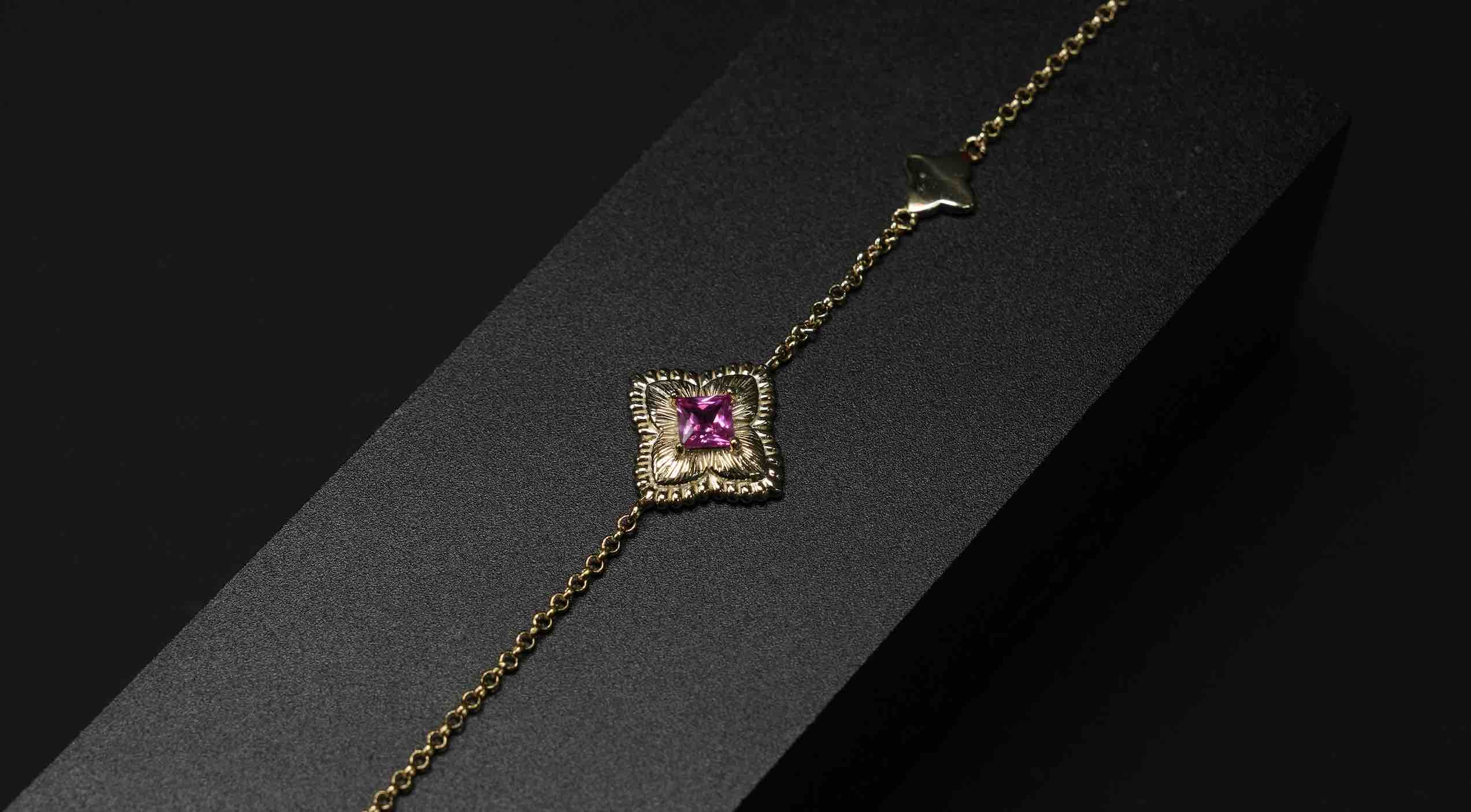

▲Carbon fiber composite filaments

With light-weight and high-density short fiber contained, carbon fiber composites take on features of high strength and ease of manufacturing. Those carbon fiber advanced materials address four pain points of average engineering materials:

- High temperature tolerance.

- Resistance to chemicals.

- High strength.

- Light weighted.

Carbon fiber composites being used in 3D printing, it combines the property merits of the composite materials with the mold fabricating advantage of 3D printing. In other words, 3D printing of carbon fiber composites gives full play to the advantages of composite materials and of addictive manufacturing, resolving the traditional problems of cumbersome molding processing and being hard to fabricate complicated structures of carbon fiber materials.

2. Industrial applications of carbon fiber composites 3D printing parts

Among various types of carbon fiber composites, we take PET-CF and PAHT-CF as illustrations, to show the applications of their 3D printed parts in engineering industries.

Industrial application example of PET-CF 3D printed parts

PET-CF is a composite material of PET material and 15% carbon fiber. No doubt that carbon fiber composite PET-CF has better mechanical performance than PET, an ordinary engineering material. PET-CF has the characteristics of low moisture-absorption rate, high strength, creep resistance, high temperature tolerance, resistance to chemical corrosion and less deformation under long-term load. PET-CF 3D printed parts are widely used on deep-water operation tools withstanding long-term stress.

In contrast to the PET printed parts that could only meet the verification standards in structural outlook, 3D printed parts of PET-CF could not only meet structural verification, but also pass the test on mechanical performance. An successful example of PET-CF 3D printed parts application in an electric tool well approves that. After making clear the application situations, the support team from Flashforge Corp. suggested the carbon fiber composite PET-CF. The internal parts of the electric tools were 3D printed on a professional 3D printer. After several tests, it showed both the strength performance and structural accuracy well met the demands. The PET-CF 3D printed parts could be directly used for tool assembly nearly with no post-processing!

▲PET-CF 3D printed parts used on the electric tools

Industrial application example of PAHT-CF 3D printed parts

PAHT-CF is the composite material made of carbon fibers and a PAHT polymer plastics. Due to the need for parts with higher strength and longer durability, Flashforge team members used PAHT-CF composite material that contains 15% carbon fiber and 3D printed the parts applying at the top four corner of the 3D printer machine (as shown in the figure below).

▲PAHT-CF 3D printing parts used on 3D printer machine

The mechanical properties of the PAHT-CF 3D printed parts were tested and verified, successfully applied to the machine and effectively ensures the machine nozzle to run stably and quickly in the XY axis.

3. What 3D printer is available for carbon fiber composites 3D printing

You’ve seen that 3D printed parts of carbon fiber composite materials were applied in various industries. However, it’s noticeable that the selection of a 3D printer and the parts’ printing quality are critical for the final applications. Available 3D printers are required to have higher-hardness nozzles that are able to tolerate long-time wear of carbon fibers, to perform stably well over long-time printing of carbon fiber composites, to be compatible with various types of carbon fiber composites, and to keep reaching high-standard printing quality. Flashforge Creator 4 3D printer is perfect to do this job. The PET-CF 3D printed parts used on the electric tool in the above example were just made via Flashforge Creator 4. It’s an industrial-grade 3D printer equipped with 3 nozzle options, among which the HS nozzle is specially designed for printing carbon fiber composites. By the way, Creator 4 3D printer inherits the dual-extruding printing system of Flashforge Creator series products, so people can simutaneously start dual nozzles on Creator 4 3D printer, to do double printing and to half printing time !

▲Creator 4 3D printer and its HS extruder

In addition, carbon fiber composite materials are prone to absorb moist in the air and keeping them in a tightly dry 3D printing environment is critical for ensuring the 3D printed parts’ fine surface quality and fine mechanical performance. A material drying station is matched with Flashforge Creator 4 3D printer as such support! This material filament drying station is designed to keep the 3D printer materials in a dry environment whether during printing, in post-printing annealing treatment, or for after-printing storage. An nice escort of Creator 4!

▲Flashforge filament drying station

In conclusion

This article introduced you to carbon fiber composites, which make the base materials reinforced with higher strength and with other properties of carbon fibers. Flashforge industrial 3D printers enable those carbon fiber composites to be 3D printed. The advanced 3D printing technology makes it possible to 3D print industrial-use parts with carbon fiber layup and with higher-strength performance. Here we mentioned the application examples of 3D printed parts of PET-CF and PAHT-CF, two carbon fiber polymer composites. To learn more application cases and useful info of 3D printing in industries, please keep your concerns on!