Comparative Analysis of MJF and MJP Technologies Executive

Summary

This report provides a comprehensive comparison of MultiJet Fusion (MJF) and MultiJet Printing (MJP) systems, prominent additive manufacturing technologies. It delves into the operating principles, key technical specifications, material capabilities, post-processing procedures, and competitive advantages of both. MJF, a powder bed fusion-based technology developed by HP, is ideal for high-speed, cost-effective production of functional parts using engineering-grade thermoplastics. Its support-free nature and high volumetric print capacity make it an attractive option for end-use parts and functional prototyping in sectors like

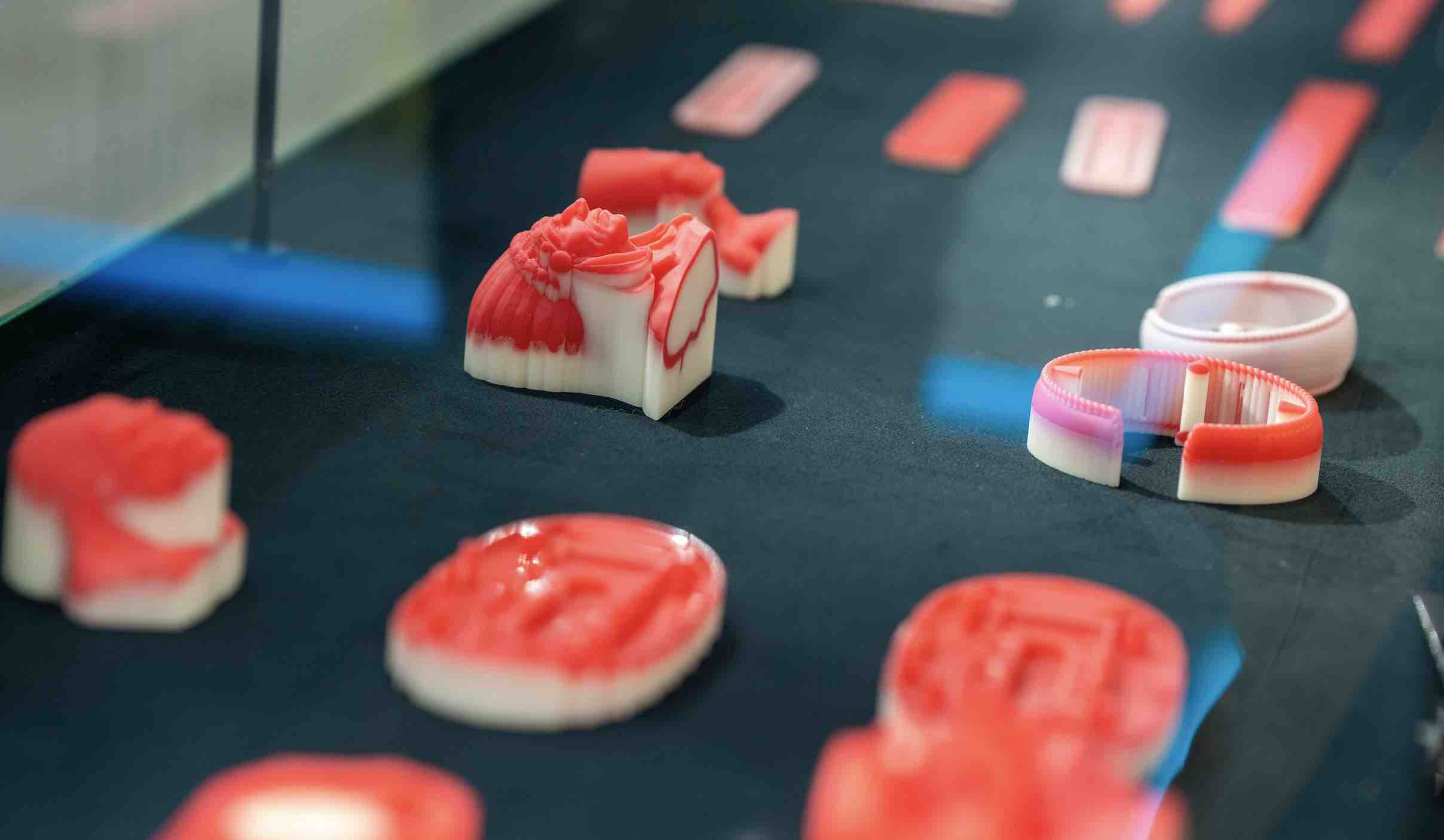

automotive and electronics. MJP, a proprietary Material Jetting technology by 3D Systems, works with photocurable resins and wax materials. MJP excels in micron-level precision, exceptional smooth surface quality, and the production of intricate geometries. Its ease of post-processing, thanks to meltable or dissolvable support structures, makes MJP indispensable in fields with high detail and aesthetic expectations, such as jewelry and dentistry.

(Example: Ring wax pattern printed by MJP 3d printer)

The report emphasizes that both technologies possess unique strengths, and the "better" technology depends on the specific application requirements, material preferences, detail level, production volume, and cost expectations. This comparative analysis aims to inform decision-makers for strategic 3D printing investments.

Introduction of 3D Printing Additive Manufacturing

1. Introduction: Overview of Additive Manufacturing TechnologiesIndustrial Significance and Evolution of 3D Printing Additive manufacturing, commonly known as 3D printing, plays a transformative role in industry due to its unparalleled design freedom, rapid prototyping capabilities, and customization potential compared to traditional manufacturing methods. These technologies offer the potential to significantly shorten product development cycles, produce highly complex geometries, and enable personalized manufacturing. By making production processes more agile and flexible, they allow companies to respond more quickly to market demands.The industrial 3D printing ecosystem encompasses various technologies, including FDM (Fused Deposition Modeling), SLA (Stereolithography), and SLS (Selective Laser Sintering). Each technology presents distinct advantages and limitations with its unique operating principles, material compatibilities, and application areas. For instance, FDM is typically used for cost-effective prototyping and large part production 1, while SLA is preferred for highly detailed models with smooth surfaces.3 SLS, on the other hand, is known for its ability to produce functional nylon parts and does not require support structures.

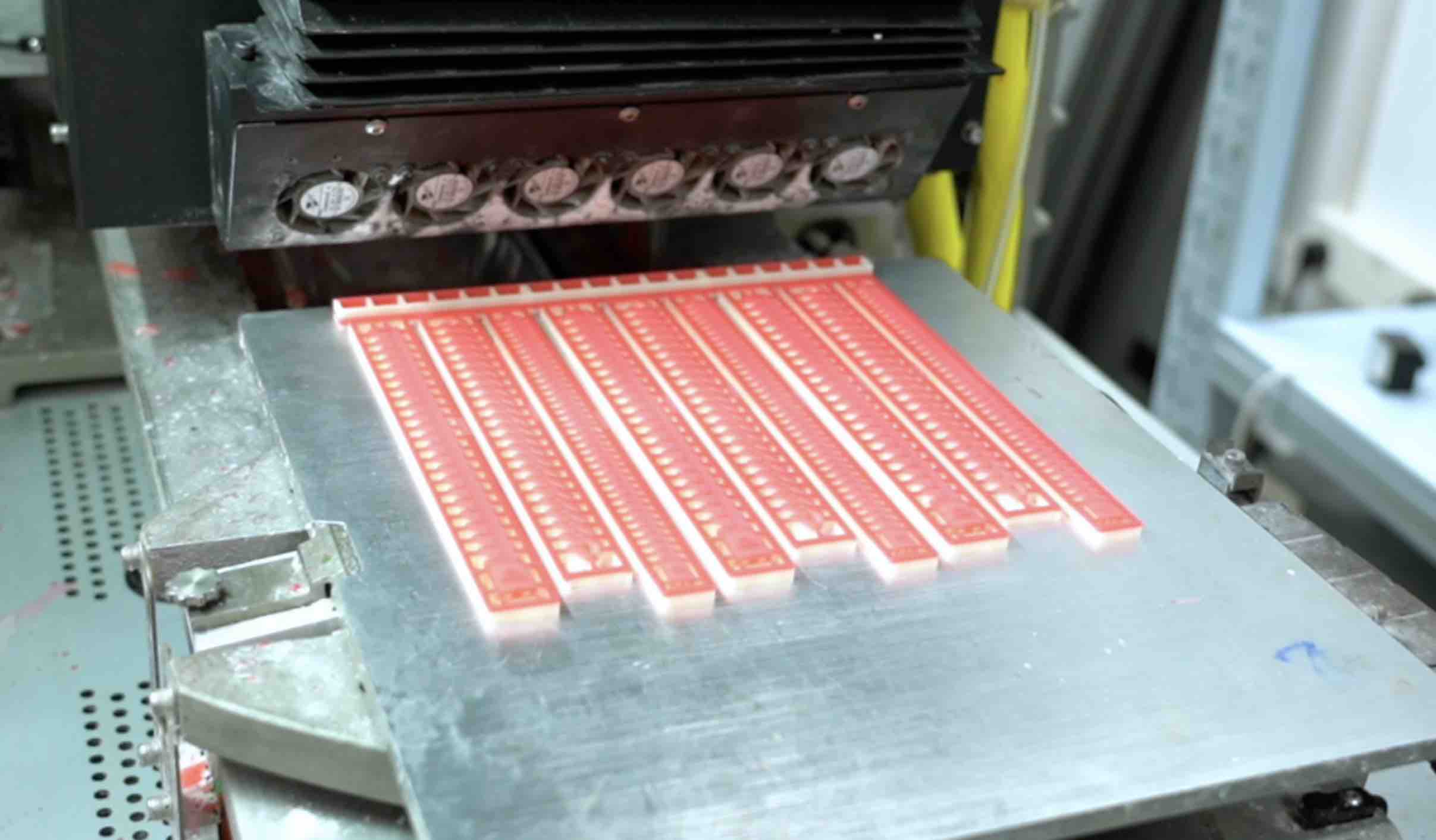

(Example: Mold printed by MJP 3d printer)

This diversity has enabled the widespread adoption of additive manufacturing across a broad industrial spectrum.

MJF vs. MJP: Technologies, Applications, and Key Differences

The Role of MJF and MJP in Additive ManufacturingMulti Jet Fusion (MJF) and MultiJet Printing (MJP) technologies, the focus of this report, hold a significant position within the additive manufacturing landscape, particularly in terms of precision, speed, and material versatility.4 These two technologies stand out in high-performance applications such as functional prototyping, end-use part production, and precision casting molds. Highlighting the overall transformation of additive manufacturing positions MJF and MJP not merely as machines with technical specifications, but as fundamental drivers of this transformation. This reveals that technology selection is not just a technical evaluation but a decision directly linked to a business's strategic objectives. The adoption of a technology plays a critical role in achieving broader business goals, such as accelerating product development processes, optimizing costs, and gaining a competitive advantage in the market.2. Multi Jet Fusion (MJF) Technology: In-depth Analysis2.1. Working Principle and Process FlowMulti Jet Fusion (MJF) is an innovative 3D printing technology developed by HP, falling under the category of powder bed fusion (PBF). This technology adopts a different approach from traditional laser-based PBF systems, offering high production speeds and homogeneous part properties.The process begins with the selective deposition of two main agents onto a powder bed: a "fusing" agent and a "detailing" agent. First, a thin layer of thermoplastic powder (typically nylon) is spread across the print bed. Then, a set of inkjet printheads (leveraging HP PageWide technology 6) precisely jet the fusing agent onto the areas where the part will be formed, and the detailing agent onto the edges of the part and areas that will not be fused. The detailing agent acts as a heat sink, preventing the powder from melting in unwanted regions, thereby enhancing the edge sharpness and dimensional accuracy of the prints. As a result, parts produced with MJF have a nearly homogeneous structure.After the agents are jetted, a heating unit applies energy across the entire powder bed. The powder particles in the regions where the fusing agent was jetted melt and coalesce, forming a solid layer.

(MJF examples)

This process occurs on an area-by-area basis, unlike traditional laser scanning methods, where an entire layer is processed simultaneously. This parallel processing capability is the key factor enabling MJF to achieve high production speeds. Once each layer is complete, the print bed lowers, and a new layer of powder is spread, repeating the process to build the part layer by layer.2.2. Key Features and Technical SpecificationsMJF technology offers superior performance metrics designed for industrial applications:Resolution: MJF printers can print with a high resolution of 1200 dpi (dots per inch).7 This high resolution allows for the accurate production of complex geometries, thin walls, and detailed features.Layer Thickness: The typical layer thickness ranges from 0.08 mm (0.003 inches) to 0.09 mm (0.0035 inches).7 This range ensures that the produced parts have sufficient detail quality while being completed within reasonable print times.Print Speed (Production Volume): MJF is considered one of the fastest 3D printing technologies in the industry, boasting industry-leading production speeds. For example, the HP Jet Fusion 5600 series can achieve volumetric speeds of up to 3,466 cm³/hr (211 in³/hr), and the HP Jet Fusion 5200 series up to 5058 cm³/hr (309 in³/hr).7 Generally, MJF has been stated to be up to 50 times faster than other 3D printing technologies 5, and specifically, it can print 1000 times faster than FDM machines 5, making it highly attractive for mass production and rapid prototyping.

(MJF examples)

Build Volume: Leading MJF models like the HP Jet Fusion 5200 and 5600 series offer a large build volume of 380 x 284 x 380 mm (15 x 11.2 x 15 inches).7 This large area allows for the production of a greater number of small parts or larger single parts in one go, increasing production efficiency.Example Models: Prominent MJF models commonly used in industrial applications include the HP Jet Fusion 5200 Series and HP Jet Fusion 5600 Series.122.3. Material Capabilities and PropertiesMJF technology primarily works with engineering-grade thermoplastic materials designed for producing functional and durable parts:Thermoplastic Nylons: The core material range for MJF consists of nylon-based polymers such as PA12 and PA11.PA12: This material stands out for its robust, durable structure and good chemical resistance. It also exhibits low friction properties, making it ideal for housings, brackets, and other general-purpose components.7 Full-color versions of PA12 are also available, enabling aesthetically rich outputs for prototypes and models.7PA11: A flexible and robust thermoplastic offering high impact resistance and elongation-at-break properties. These characteristics make it suitable for applications such as snap-fit connectors, gears, bearings, sports goods, and living hinges.7PA12 Glass Beads: PA12 reinforced with glass beads provides high stiffness and excellent dimensional stability. This material is preferred for applications requiring high rigidity, such as enclosures, fixtures, and tooling.9TPU (Thermoplastic Polyurethane): MJF also supports TPU material, which is suitable for producing flexible and rubber-like parts. It is used in applications such as gaskets, seals, and other flexible components.5MJF materials offer excellent isotropy and high durability, ensuring that the produced parts have similar mechanical properties in different directions.7 This feature ensures consistent part performance regardless of orientation, which is critical for functional applications.2.4. Post-Processing ProceduresOne of the most significant advantages of MJF technology is that it does not require support structures during printing.6 This not only increases design freedom but also significantly reduces post-print processing time and cost. Typical post-processing steps for MJF parts include:Depowdering: The first step after printing is to carefully extract the parts from the build chamber and remove excess powder using high-pressure air or specialized tools.17 Proper depowdering directly affects the quality of subsequent processes.Bead Blasting: After depowdering, bead blasting is applied to further smooth the surface of the parts and remove any remaining loose powder particles. In this process, fine, rounded media is blasted onto the part's surface at high velocity. Bead blasting gives parts a more uniform and homogeneous appearance and prepares the surface for subsequent processes like dyeing or vapor smoothing.17Vibratory Finishing: To improve surface roughness, parts are tumbled in a drum filled with ceramic media. This method is particularly effective for deburring and polishing parts with intricate grooves and corners, resulting in a smoother, more satin sheen.5Vapor Smoothing: Chemical vapors are used to achieve a smoother, glossier, and sealed surface. This process creates a controlled melt on the outermost surface of the part, minimizing surface blemishes and troughs. The result is a glossy finish that enhances aesthetics, part strength, and fluid resistance.17Dyeing and Coloring: MJF parts are typically produced in a natural gray color.17 To achieve the desired color, parts can be immersed in hot dye baths. This method allows the dye to penetrate the part's surface up to 200 µm, providing a more durable and homogeneous color compared to spray painting.5 In the automotive industry, this process is often preferred for dyed black parts.17Electroplating: It is also possible to make the surface of MJF parts conductive for metal plating. This process not only gives parts an aesthetic appearance but also serves as a functional coating that reduces surface roughness.72.5. Advantages Over Competitors (excluding MJP)Multi Jet Fusion technology offers a range of significant advantages compared to other 3D printing methods:Speed and Productivity: MJF offers significantly faster production speeds compared to many other 3D printing technologies (SLS, FDM, SLA, Colorjet).6 It has been stated to be 1000 times faster than FDM and 6-1000 times faster than others.5 This high speed provides a major competitive advantage, especially in high-volume production and rapid prototyping processes.Cost-Effectiveness: MJF can offer cost reductions of up to 30-80% compared to SLS and FDM.5 This cost advantage stems from factors such as the high recyclability of the powder and the absence of support structures.Mechanical Properties and Part Quality: It delivers high mechanical strength, an excellent strength-to-weight ratio, and homogeneous part quality with production-grade nylon PA-12 materials.5 These properties make MJF an ideal technology for functional prototypes and end-use parts.No Support Structure Requirement: The absence of support material during printing is a fundamental design advantage of MJF.6 This feature increases design freedom, allows for easy production of complex internal geometries and lattice structures, and significantly reduces post-processing costs and time. The lack of support structures shortens post-print cleaning and processing times, and also allows for a higher packing density in the build chamber, enabling more parts to be produced per print. This enhances overall production efficiency and forms the basis for MJF offering a faster and more cost-effective manufacturing solution.Surface Quality (with Less Post-Processing): Thanks to the use of a detailing agent, MJF can achieve fine detail resolution and a smoother surface than SLS.Repeatability and Accuracy: Consistent and repeatable results are achieved across different prints due to calibrated print modes and hardware reliability.7 This simplifies quality control in mass production environments.Material Limitations vs. Speed Balance: While MJF is touted as "the fastest 3D printer in the world" 5, its material options are primarily limited to nylon-based polymers and TPU.5 This speed advantage applies to these specific material types and applications and does not imply universal superiority for all material needs. This indicates that material compatibility is a critical factor when evaluating MJF's speed potential. In other words, speed is closely tied to the nature of the materials used, and this limitation should be considered when choosing the most suitable technology for a particular application.Focus on Engineering-Grade Applications: The emphasis on engineering-grade thermoplastics 5 and functional prototypes/end-use parts 5 distinguishes MJF from other technologies that focus solely on visual aesthetics or simple prototyping.

(MJF 3D printer examples)

This positions MJF as a strong option for demanding, performance-critical applications. This focus suggests that MJF can go beyond merely being a prototyping tool and participate in actual production processes. This specialization allows MJF to gain broader acceptance in industrial manufacturing and offer a true alternative to traditional manufacturing methods.2.6. Typical Application Areas and Model ProductionMJF technology has a wide range of applications due to its speed, durability, and cost-effectiveness:Functional Prototyping: Ideal for producing fast, strong, and cost-effective functional prototypes.5 It accelerates design iterations, shortening product development cycles.End-Use Parts: Suitable for industrial-strength parts and final products in high-volume production.5 This offers an economical alternative to traditional methods, especially for low-to-medium volume series production.Automotive Industry: Used for lightweight parts, prototypes, and end-use components. It offers a preferred post-processing option for dyed black parts.5 Case studies, such as Capitol Group's production of 3D printed hanger parts for automotive clients, demonstrate MJF's practical applications in this field.22Electronics: Provides suitable materials for components requiring ESD (Electrostatic Discharge) and RFI (Radio Frequency Interference) ratings or having conductive properties.5 This is critical for housings or internal components of sensitive electronic devices.Medical Applications: Production of biocompatible parts is possible with medical-grade and chemical-resistant materials.5 This creates potential use cases for prosthetics, orthotics, and certain medical device components.Tools, Fixtures, and Jigs: Produces durable parts for applications subjected to high mechanical stress and wear.5 It enables rapid and cost-effective production of custom tools used in manufacturing lines.Complex Geometries: MJF can create complex internal structures and geometries that are impossible to produce with traditional CNC machining methods.8 This grants designers the freedom to explore forms and functions previously unattainable.Architectural Models, Sculpture, and Creative Arts: HP's case studies across various industries demonstrate the broad application range of this technology.9 It is particularly valuable for rapid prototyping and producing complex forms.

(MJP examples)

3. MultiJet Printing (MJP) Technology: In-depth Analysis3.1. Working Principle and Process FlowMultiJet Printing (MJP) is a proprietary material jetting (MJ) technology by 3D Systems. This method operates on a principle similar to conventional inkjet printers but uses specialized materials to build three-dimensional objects.The process begins with the deposition of micron-sized droplets of photocurable liquid resins or casting wax materials layer by layer onto a build platform, using piezo printhead technology. Immediately after each layer of material droplets is jetted, a UV light source (UV bulbs), part of the same printhead carriage movement, instantly cures and solidifies it. This immediate curing ensures rapid layer accumulation and maintains high dimensional accuracy.Once the first layer is complete, the build platform lowers by one layer thickness, and the process repeats until the object is fully formed. This layered accumulation process enables the production of parts with intricate internal details and smooth external surfaces.A distinguishing feature of MJP technology is the creation of support structures from a specialized material. This support material can be easily removed after the printing process is complete, either by melting or dissolving in a special solvent bath. This "hands-free" support removal method ensures that delicate parts and those with complex internal cavities are thoroughly cleaned without the risk of damage during manual cleanup. This is a significant reason why MJP is preferred for highly detailed and precise applications.3.2. Key Features and Technical SpecificationsMJP printers are characterized by their high resolution, fine detail capability, and compatibility with various materials:Resolution and Detail: MJP printers offer very high resolution and fine detail capability. They can provide the highest Z-direction resolution with layer thicknesses as low as 16 microns.For the Plempire PL2000 Plus, an XHD Mode resolution of 1200x1200x1600 DPI and a layer thickness of 0.016 mm are specified.23 This is ideal for applications where fine details are critical, such as jewelry.The Flashforge WaxJet 530 boasts a remarkable 2900x2900x1700 DPI resolution and a 15 µm layer thickness. This translates to extremely smooth surfaces and virtually invisible layer lines.The Solidscape S350 offers an impressive resolution of 5000x5000 dots/inch (197x197 dots/mm).26Layer Thickness: MJP offers very fine layer thicknesses, ranging from 8 µm (3D Systems MJP 300W ZHD mode 29) to 16 µm (Plempire PL2000 Plus 23, 3D Systems MJP 300W XHD mode 29). For the Solidscape S350, user-selectable layer thicknesses from 0.00025 inch (0.00635 mm) to 0.003 inch (0.0762 mm) are available.26 These fine layers maximize the surface smoothness and detail accuracy of the final parts.Print Speed (Z-axis): Speed varies depending on the printer model and selected print mode.Plempire PL2000 Plus (XHD Mode): Features a Z-axis speed of 7.50 mm/hr in single lane printing, 3.50 mm/hr in two-lane printing, and 2.40 mm/hr in three-lane printing. These figures indicate that individual part speed decreases when more lanes are used, but the overall production throughput (due to more parts being printed simultaneously) can increase. This reveals that "more channels" is a trade-off aimed at optimizing overall production capacity rather than increasing the print speed of a single part. This is an important detail, especially for users considering batch production.3D Systems MJP 2500W Plus (XHD Mode, single lane): Has a production capacity of 147 cm³/hr (9 in³/hr).30Flashforge WaxJet 530: Can achieve a high print speed of 6.35 mm/h thanks to its triple printheads. It also has the capacity to produce 10-12 kg of wax models per month , making it suitable for high-volume wax casting applications.Build Volume: MJP printers offer various build volumes:Plempire PL2000 Plus: 294 x 212 x 150 mm.233D Systems MJP 300W/2500W Plus: 294 x 211 x 144 mm.29Flashforge WaxJet 530: 289 x 208 x 150 mm.Solidscape S350: 152.4 x 152.4 x 101.6 mm.26UnionTech Cute 300: 250 x 140 x 240 mm.Example Models: Leading printer models utilizing MJP technology include the Plempire PL2000 Plus, 3D Systems MJP 300W/2500W Plus, Flashforge WaxJet 530, Solidscape S350, and UnionTech Cute 300.3.3. Material Capabilities and PropertiesMJP technology caters to a wide range of industrial and aesthetic applications by utilizing a broad spectrum of photopolymer resins and wax-based materials :Casting Wax: Specifically formulated 100% wax materials are used, particularly for jewelry and industrial casting applications. These include VisiJet Wax Jewel Ruby, VisiJet Wax Jewel Red, VisiJet M2 CAST (from 3D Systems), and Plempire YHK Wax.These wax patterns integrate seamlessly with traditional lost-wax casting processes. They ensure flawless castings due to zero ash residue and clean burnout properties, preventing residue-induced defects in precious metal casting.Waxes offering high durability and flexibility are ideal for producing models involving stone setting and complex geometries. This feature is critical for intricate jewelry designs like micro-pavé and filigree.Rigid Plastics: Materials that offer the look and feel similar to injection-molded parts. Available in various colors such as white, black, clear, gray, and tan. These materials are used for concept modeling, form and fit testing.Elastomeric Materials: Flexible materials that provide rubber-like functionality with high elongation and Shore A hardness. These are suitable for gaskets, seals, and flexible prototypes.High-Temperature Materials: Used for parts requiring high stability, with heat deflection temperatures up to 250°C.4 This is important for prototypes or molds that will be exposed to heat.Biocompatible Materials: Specifically developed materials for medical and dental applications, compliant with USP Class VI and/or ISO 10993 standards.4Multi-Material Composites: MJP offers the unique ability to combine multiple base materials or mix rigid and elastomeric materials in a single print to achieve custom performance characteristics. This allows for creating parts with varying hardness or flexibility zones within a single object.3.4. Post-Processing ProceduresMJP technology significantly simplifies and accelerates post-processing procedures by utilizing meltable or dissolvable support materials. This makes the support removal process virtually "hands-free" and minimizes the need for manual labor.Support Removal: For wax-based supports, parts are typically immersed in a heated solvent bath or water bath after printing to dissolve or melt away the support material. For example, for the Flashforge WaxJet 530, supports dissolve completely in a solvent bath at 43°C, leaving almost no marks. This method eliminates issues like manual support removal and surface scarring often seen in FDM or some SLA technologies.Minimal Finishing: Due to the inherently high surface quality of MJP parts, they often require minimal to no post-finishing.38 This preserves surface integrity, especially in delicate and complex parts, and reduces the need for additional steps like polishing. After support cleaning, light brushing or polishing steps may be applied in some cases to remove any residual film.41 Coating and polishing processes are also available for Stratasys PolyJet parts.

(MJP examples)

42MJP's easy and hands-free post-processing capability directly ensures its ability to produce superior surface quality and intricate details without damage. Unlike FDM or some resin printers that require manual support removal, where the process can mar the surface, MJP's method preserves fine features, making it ideal for aesthetic and high-precision applications. This significantly reduces post-processing time and cost, especially in sectors like jewelry where precious metals are involved.3.5. Advantages Over Competitors (excluding MJF)MultiJet Printing technology offers a range of unique advantages compared to other 3D printing methods:High Resolution and Detail: MJP offers higher resolution and finer details compared to other photopolymer-based technologies (like SLA). Specifically, layer thicknesses as low as 16 microns 4 enable the production of very precise and intricate parts. This is a significant superiority, especially in applications where small and complex geometries are critical.Smooth Surface Quality: Very smooth and aesthetically appealing surfaces are achieved, thanks to a "glossy" print mode. Surfaces on wax models that require virtually no finishing 38 significantly reduce the time and cost of polishing precious metals. This directly impacts the quality of the final product.Material Versatility and Blending Capability: MJP is one of the rare technologies that can combine different materials in a single print and mix resins during printing. This feature allows for the production of composite parts with varying mechanical properties (e.g., parts with rigid and flexible zones), increasing design flexibility.44Color and Texture Realism: It enables objects to appear with excellent realism. It is widely used for design, prototyping, demonstration models, and educational applications. Resin combinations can mimic the color and texture of other materials, making MJP ideal for visual prototyping and marketing materials.Seamless Integration with Lost-Wax Casting: It integrates seamlessly with traditional jewelry and industrial casting processes.34 This eliminates time-consuming and costly traditional methods, enhancing production efficiency. Wax models produced with MJP leave minimal residue after casting due to their clean burnout properties.Easy and Hands-Free Post-Processing: The post-processing procedure is simplified and minimizes manual labor due to meltable/dissolvable supports. This directly ensures its ability to produce superior surface quality and intricate details without damage. Unlike FDM or some resin printers that require manual support removal, MJP's method preserves fine features, making it ideal for aesthetic and high-precision applications. This feature significantly reduces post-processing time and cost, especially in sectors like jewelry where precious metals are involved.Specialization in Jewelry and Dentistry: MJP technology, particularly with wax materials, has carved out a strong niche in the jewelry and dental sectors.41 This specialization stems from its ability to produce highly detailed, smooth, and clean-burning wax patterns, which are critical for precious metal casting. This indicates that MJP directly addresses the unique demands of these specialized industries, becoming a preferred solution in these fields.3.6. Typical Application Areas and Model ProductionMJP technology is widely used in areas where high precision and aesthetics are critical, thanks to its high precision and detail capabilities:Jewelry: MJP has become a standard technology for producing ultra-precise, directly castable wax patterns in the jewelry industry.Ideal for producing intricate details for complex geometries, micro-pavé, filigree, and embedded stones.Supports personalized jewelry production and rapid prototyping processes.41Dentistry: Produces highly accurate parts for various dental applications, including dental models, crown and bridge (C&B) structures, thermoforming molds, aligner models, and removable partial dentures (RPD).High accuracy and dimensional stability ensure the production of patient-specific devices.49Printers like the UnionTech Cute 300 offer high-volume dental production capacity, such as over 32 aligner models per day.48Industrial Casting: Used to produce casting patterns for precision metal parts. It is common in the production of industrial components using the lost-wax casting technique.Concept Modeling and Functional Prototyping: Used for rapid design iteration, watertight applications, and flow visualization in prototyping needs.Rapid Tooling: Ideal for rapid tool production, such as molds, dies, and jigs.Education: Also used in educational settings for 3D printing solutions and applications.51Architectural Models: DLP-based MJP printers, such as the UnionTech Cute 300, also find application in the production of architectural prototypes.524. MJF vs. MJP: Direct Comparative Analysis4.1. Technological Differences and SimilaritiesMulti Jet Fusion (MJF) and MultiJet Printing (MJP) technologies, while both offering high performance in additive manufacturing, exhibit significant differences in their fundamental operating principles and the materials they utilize.MJF: A powder bed fusion technology developed by HP. In this process, thermoplastic powders (typically nylon) are spread onto a powder bed, and fusing and detailing agents are jetted to bind them with heat. One of MJF's most distinctive features is that it does not require any support structures during printing; parts are supported by the surrounding unfused powder bed. This increases design freedom and significantly reduces post-processing time.MJP: A proprietary material jetting technology by 3D Systems. In this method, photocurable liquid resins or waxes are jetted as micron-sized droplets via piezo printheads and instantly cured and solidified by UV light. MJP requires meltable or dissolvable support materials during printing. However, these supports can typically be removed hands-free in a heated bath, ensuring the preservation of delicate details.

(MJP examples)

Similarities: Both technologies are capable of delivering high precision and detail in additive manufacturing. Both are designed for industrial applications and can produce complex geometries.4 Additionally, both technologies support digital workflows, optimizing design and production processes, which contributes to accelerating product development cycles.44.2. Performance Metrics ComparisonThe performance metrics of MJF and MJP reveal their strengths, which vary according to different application needs:Resolution and Detail:MJP: Generally offers finer layer thicknesses (down to 8 µm 29) and consequently smoother surface finishes. It excels particularly in applications requiring very fine detail and surface quality, such as jewelry.38 The 5000x5000 dpi resolution of Solidscape S350 26 and the 2900x2900x1700 DPI resolution of Flashforge WaxJet 530 53 highlight their capabilities in this area.MJF: Offers 1200 dpi resolution 7 and layer thicknesses of 0.08-0.09 mm.7 It can achieve fine detail resolution thanks to the detailing agent, but it may differ in achieving the visual smoothness and aesthetic detail level provided by MJP. MJF parts typically have a more granular surface texture, which can be smoothed with additional post-processing like vapor smoothing.Print Speed:MJF: Is significantly faster than MJP in terms of volumetric production speed. The HP Jet Fusion 5200 series can reach speeds of up to 5058 cm³/hr.8 This makes MJF advantageous for rapid production of large volumes of functional parts. The ability of MJF to process an entire layer simultaneously is the primary reason for this speed difference.MJP: Z-axis speeds (e.g., 7.50 mm/h for single lane in Plempire PL2000 Plus ) are lower compared to MJF.

(MJP examples)

However, multi-printhead systems like the Flashforge WaxJet 530 can boost overall throughput, producing 10-12 kg of wax models per month. While the individual part speed might decrease as the number of "channels" in MJP increases, the ability to print more parts simultaneously enhances batch production capacity. This indicates that when evaluating MJP's speed, the total job throughput rather than just the print time of a single part should be considered.Build Volume: MJF printers (e.g., HP Jet Fusion 5200/5600 series at 380 x 284 x 380 mm 7) generally offer larger build volumes compared to MJP printers (e.g., Plempire PL2000 Plus at 294 x 212 x 150 mm 23). This suggests that MJF might be more suitable for producing larger single parts or a greater number of small parts in one go.The following table summarizes the key characteristics of MJF and MJP technologies, providing a direct comparison:FeatureMulti Jet Fusion (MJF)MultiJet Printing (MJP)Technology PrinciplePowder Bed FusionMaterial JettingMaterial FormThermoplastic Powders (Nylon, TPU) 5Photocurable Liquid Resins, Waxes 4Support StructureNot Required (Powder bed provides support) 6Required (Meltable/Dissolvable Wax or Resin)Typical Resolution1200 dpi 71200-5000 dpi (XY), 8-16 µm layer thickness (Z) 53Layer Thickness0.08 - 0.09 mm 70.00635 - 0.0762 mm (8-16 µm typical) 29Volumetric SpeedHigh (e.g., up to 5058 cm³/hr) 8Medium (Z-axis 2.4-7.5 mm/hr, throughput increased with multi-heads) 53Surface QualitySmooth (after post-processing), homogeneous 5Very smooth, high aesthetic detail 38Post-ProcessingDepowdering, bead blasting, dyeing, vapor smoothing 17Support dissolution/melting (hands-free), minimal polishingMaterial VarietyNylon (PA11, PA12, glass-filled), TPU 5Wax, Rigid Plastics, Elastomeric, High Temp, Biocompatible, Multi-Material 4Typical ApplicationsFunctional prototypes, end-use parts, automotive, medical, jigs, fixtures 5Jewelry, dentistry, precision casting patterns, aesthetic models, rapid tooling 344.3. Material and Application Areas ComparisonMJF and MJP are differentiated by their distinct material capabilities and the application areas shaped by these capabilities:Material Types:MJF: Primarily works with engineering-grade thermoplastic polymers like PA11, PA12, and TPU.5 These materials offer properties such as high strength, durability, chemical resistance, and heat resistance. This makes MJF suitable for producing functional prototypes and end-use parts.MJP: Offers a broader range of materials, including photocurable resins and 100% wax materials. This range extends from rigid plastics to elastomeric and biocompatible materials. The use of wax materials, in particular, makes MJP ideal for producing precision casting patterns that can directly integrate with lost-wax casting processes.34 Furthermore, the ability to combine or mix different materials in a single print provides MJP with a significant advantage in terms of design and application flexibility, enabling the production of complex and multi-functional parts.

(MJP examples)

Typical Part Characteristics:MJF: Parts produced are generally strong, durable, and functional. Surface quality can be improved with post-processing like bead blasting or vapor smoothing, but achieving the natural smoothness and aesthetic detail of MJP may require additional effort. MJF parts exhibit homogeneous mechanical properties and high isotropy, ensuring consistent performance regardless of orientation.5MJP: Parts produced, especially wax models, feature exceptionally smooth surface finishes and very fine details.34 This is a major advantage in fields like jewelry and dentistry where aesthetics and precision are critical. MJP's color and texture realism also make it ideal for visual prototypes and demonstration models.4.4. Cost and Workflow ImplicationsAs both technologies offer industrial-grade 3D printing solutions, their cost and workflow implications play a significant role in investment decisions:Initial Investment Cost: Both technologies represent industrial-grade 3D printing solutions, so initial investment costs are generally high. While some MJP printers like the Solidscape S350 start from around $35,650 14, the 3D Systems MJP 300W is approximately $66,700 . The Flashforge WaxJet 530 can be around ₹ 5,200,000 (approximately $62,000) . MJF printers also fall within an industrial scale, often requiring a substantial investment.Material Costs:MJF: Generally offers lower cost per part compared to other 3D printing technologies.5 This is achieved through the high recyclability of the powder and the absence of support material requirements.9 Material utilization efficiency helps MJF reduce long-term operating costs.MJP: Resins and wax materials are typically more expensive than MJF powders. However, especially in wax casting applications, the precision and ease of post-processing achieved with MJP can lead to overall cost savings compared to traditional methods. Systems like the Flashforge WaxJet 530 enhance cost-effectiveness by achieving a material utilization rate of 58-60% and up to 78% savings on support structures.53 This can offset the higher material cost in the production of high-value items.Post-Processing Complexity and Cost:MJF: Since it does not require support material, the post-processing workflow is simplified, primarily involving excess powder removal and surface finishing.17 This reduces labor costs and total production time, which is a significant advantage in high-volume manufacturing.MJP: Post-processing is typically "hands-free" and fast due to meltable or dissolvable supports. This preserves surface integrity, especially in complex and delicate parts, and minimizes the need for manual polishing.

(MJP examples)

This allows MJP to offer a significant advantage, particularly in sectors like jewelry where post-processing can be very time-consuming and costly.4.5. Which Technology is Better? Decision-Making Criteria The choice of the "better" technology depends entirely on the specific requirements of the application and the priorities of the business. Both technologies excel in different niches.Application Area and Purpose:

MJF: Should be preferred for functional prototypes, end-use parts, high-volume production, and situations where durability and mechanical strength are paramount. It is ideal for automotive, electronics, and general industrial manufacturing. If the final part's performance and cost-effectiveness are the primary concerns, MJF is a more suitable option.

MJP: Excels in applications requiring aesthetic detail, smooth surface quality, intricate geometries, and especially direct integration with lost-wax casting processes. It is indispensable in fields like jewelry, dentistry, precision casting, and visual prototyping. If the product's visual appeal and precise details are critical, MJP offers a more suitable solution.Material Needs:MJF: Suitable for those who need to leverage the mechanical properties (durability, flexibility, chemical resistance) offered by nylon-based thermoplastics and TPU.MJP: Offers a wider material selection for those needing wax, clear, flexible, biocompatible, or composite parts that combine different material properties in a single print.Detail and Surface Quality:MJP: Is the better choice if very high detail resolution at the micron level and a smooth surface finish are critical. This is particularly important for products like jewelry and dental models that need to be aesthetically flawless.MJF: Provides sufficient detail and surface quality for functional parts, but may not be as aesthetically refined as MJP. Surface quality can be improved with post-processing, but this requires an additional step.Production Volume and Speed:MJF: Offers higher volumetric efficiency for rapid mass production of large volumes of functional parts. The absence of support structures allows the build chamber to be fully packed, enabling more parts to be produced simultaneously.MJP: While it can increase total part count in batch production (thanks to multi-channels), the print speed of a single part might be slower compared to MJF. However, in niche areas like jewelry and dentistry, the precision and specialized material capabilities offered by MJP may take precedence over raw speed.Cost Criteria:MJF:

(MJP examples)

May be more suitable for those looking to reduce cost per part and minimize post-processing labor. Its high material recycling rate also contributes to cost-effectiveness.MJP: Although material costs might be higher, the ease of post-processing and the added value derived from the final product quality can offset the cost, especially for high-value products (like jewelry) or medical applications where precision is critical.

Conclusion and Recommendations

Multi Jet Fusion (MJF) and MultiJet Printing (MJP) technologies offer powerful capabilities in distinct yet complementary areas of additive manufacturing. Both technologies provide significant advantages over traditional manufacturing methods and contribute to the digital transformation of industries.MJF is an optimized solution for the production of high-volume, functional, and durable thermoplastic parts. Its support-free nature, high volumetric print speed, and cost-effectiveness make MJF an ideal choice for general industrial prototyping, end-use part production, and applications in sectors like automotive and electronics. This technology offers a significant advantage for businesses looking to accelerate production cycles and reduce labor costs.MJP, on the other hand, leads in applications requiring micron-level detail, exceptional smooth surface quality, and direct integration with wax casting processes. Its ease of post-processing, thanks to meltable or dissolvable support structures, provides unique value in producing complex aesthetic parts and precision casting patterns. These features make MJP indispensable in sectors like jewelry and dentistry, where the visual quality of the product and the need for minimal post-casting processing are critical.In conclusion, there is no single "better" technology; rather, the optimal choice depends entirely on the specific requirements of the application and the priorities of the business. When making a technology selection, factors such as the purpose of the part to be produced (functional vs. aesthetic), the required level of detail, the preferred material type, production volume, and total cost (including initial investment, material, and post-processing) should be carefully evaluated. This evaluation will help businesses maximize the potential of additive manufacturing and achieve their strategic goals. It is recommended that businesses analyze their specific needs and market requirements to determine which of these two advanced 3D printing technologies is most suitable for them.

——— Written by Amir Yılmaz