【Printing Guidance】The Influence of Filament Dryness and Humidity on Printing Effect

The dryness and humidity of filaments have a significant impact on the 3D printing effect, especially for filaments with high moisture absorption. When these filaments are exposed to a humid environment for a long time, they will absorb moisture, leading to a decrease in their quality. When damp filaments are extruded into the hot end of the 3D printer and heated, the water inside them will boil at a high temperature of around 200-300°C as the filament melts, resulting in the formation of bubbles or gas. This can lead to poor print quality, interlayer adhesion, bubbles, cracks, and other issues.

In a humid environment, the types of filaments that are prone to moisture absorption include: ABS, PA, PC, PETG, PVA, TPU, carbon fiber composite materials, etc.

- ABS (Acrylonitrile Butadiene Styrene): If ABS absorbs moisture, it may result in bubbles during the printing process or a decrease in print quality.

- PA (Nylon): Moisture-absorbed nylon may cause bubbles during printing or affect the strength and quality of the prints.

- PVA (Polyvinyl Alcohol): PVA is a water-soluble support material that is highly susceptible to moisture absorption. Moisture-absorbed PVA becomes very soft, which can result in difficulties in feeding properly, support structure failure, or poor printing outcomes.

- Carbon fiber composite materials (PAHT-CF/PET-CF/PLA-CF, etc.): Carbon fiber composite materials consist of carbon fiber and resin. When the carbon fiber absorbs moisture, the resin becomes damp, leading to a decrease in performance and reducing the overall strength and rigidity of the structure. It may also cause bubbles or voids during printing, affecting the surface smoothness of the printed object, or even result in cracking.

Currently, a common method used in the industry is to vacuum package filaments in aluminum foil bags at the production end, and equip the 3D printer with a dedicated filament drying chamber, which is used in a sealed manner with desiccants. If the filaments are damp due to long storage, a dedicated drying chamber can be used to dry the filaments and restore their performance. Flashforge's recently released high-speed dual-extruders industrial 3D printer, the Guider 3 Ultra, is equipped with a sealed filament drying chamber integrated with the machine body. When used with desiccants, it can maintain humidity below 10% within 5 days. At the same time, the material chamber is equipped with a humidity sensor to accurately detect the humidity inside the chamber.

In this comparative experiment, we will use PAHT-CF as the main printing material and S-PAHT as the support material. Next, we will compare the preparation before printing, the printing process.

For the first group, we will strictly follow the drying standard for each step:

1. Place the materials in a drying oven and set it to 110°C for 8 hours to thoroughly dry the filaments and restore their performance.

2. Load the dried consumables quickly, placing 3 packs of desiccants in each consumable drying chamber, and close the lid with the humidity sensor turned on.

3. Observe the humidity sensor until the humidity successfully decreases to 15% or below, ensuring a dry environment inside the chamber.

4. Start the printing process and observe the printing effect for any issues such as material leakage, stringing, or adhesion.

For the second group, we will directly print with damp filaments:

1. Step 1: Load the damp filaments directly and turn on the humidity sensor. The humidity in the environment is around 60%. In such a humid summer environment, the filaments are prone to dampness.

2. Step 2: No need to place desiccants or close the chamber lid.

3. Step 3: Start the printing process and observe. The damp materials will produce a "crackling" sound during printing, the extrusion lines will be uneven, and the surface may have abnormal textures.

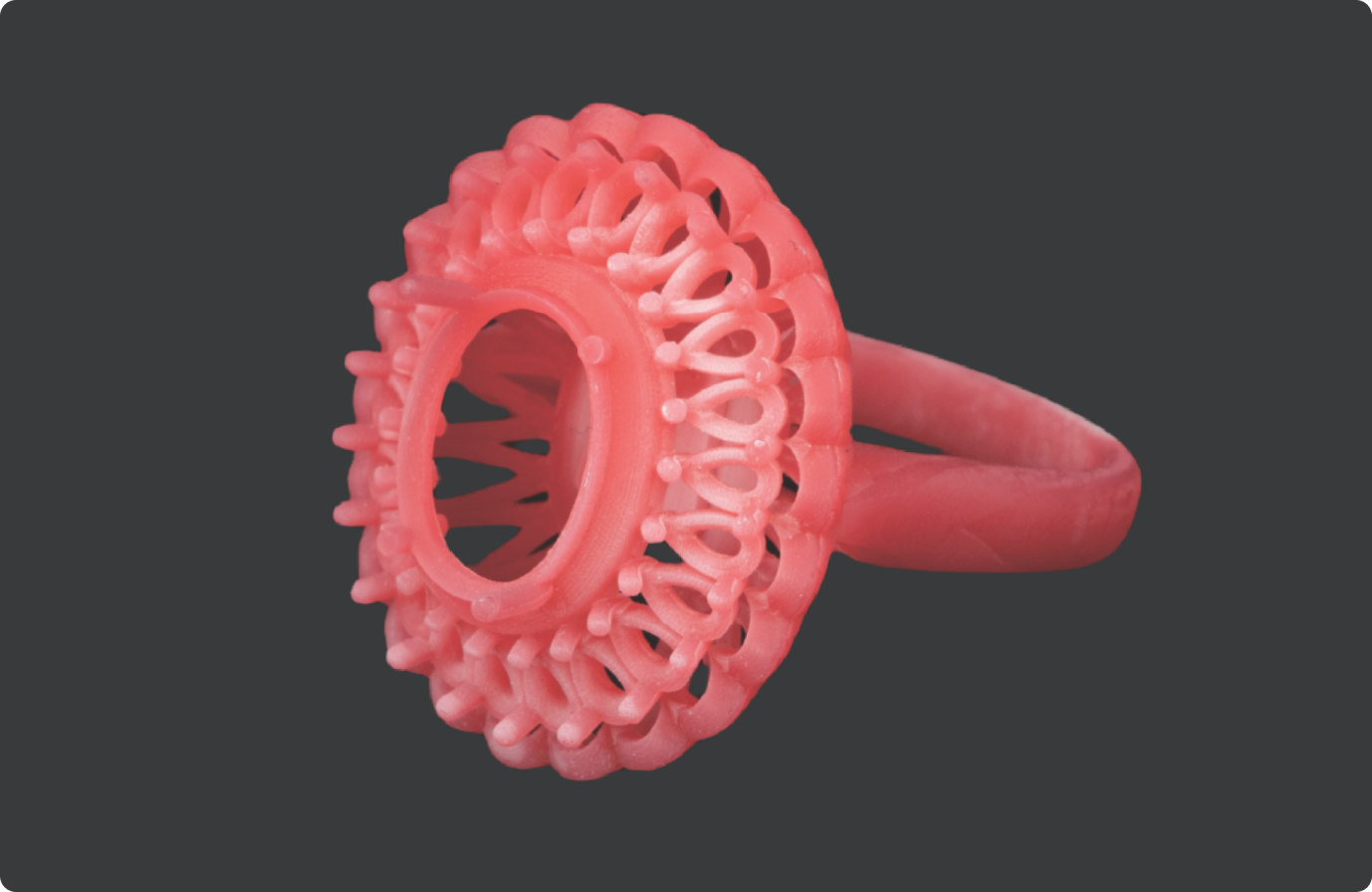

The two images below compare the printing results with and without the use of a sealed filament chamber to maintain dryness. In normal circumstances, a single print job can range from a few hours to several tens of hours. During this long period, it is crucial for the filaments to remain dry to ensure the quality of the final printed object. The differences between the two groups' printing results are quite evident. The samples printed with dry filaments have a smooth, fine, clean, and tidy surface, with no visible stringing. On the contrary, the samples printed with damp filaments exhibit rough, stringy, and severely leaked surface textures.

Flashforge Guider 3 Ultra and Guider 3 Plus are both equipped with sealed filament drying chambers, ensuring optimal printing results. In addition to this feature, Flashforge has also introduced a filament dring station. This drying station can heat up to 120°C, effectively drying damp filaments and restoring their performance. The drying station has a large storage space, capable of accommodating up to 6 rolls of 1kg filaments. Moreover, it comes with built-in silica gel desiccants to ensure that dried filaments can be stored for extended periods of time.

About Flashforge

Flashforge is a leading brand in the global 3D printer industry. Flashforge has deeply cultivated the needs of 3D printing industry and launched a new series of FDM 3D printers. The high-speed Guider series 3D printers feature high-speed prototyping, enabling rapid prototyping and manufacturing; the performance-focused Creator series 3D printers, with high-temperature chambers, are suitable for 3D printing engineering materials, carbon fiber and glass fiber composite materials. Flashforge, with products of stable and reliable 3D printers, high-quality 3D printing materials, professional slicing software and comprehensive after-sales service, provides small and medium-sized enterprises with a full range of 3D printing digital solutions for rapid manufacturing, accelerates design iteration and productization, and leads the new future of 3D printing in intelligent creation.