Medit Partners with Flashforge: Application of Digitization in Dentistry

Today, the force of innovation drives collaboration across various fields, unlocking unprecedented possibilities. Recently, Medit, a prominent leader in the dental industry, has embarked on a remarkable collaboration with Flashforge. This partnership seamlessly integrates their innovative intraoral scanning technology with Flashforge's leading 3D printing software, heralding a remarkable revolution for the entire industry. This article delves into the origin, outcomes, and industry implications of this cross-industry collaboration.

Origin of Collaboration:

1. Medit Overview:

Medit is a company dedicated to developing 3D intraoral scanners for clinical applications. While experiencing rapid growth, its market share in the global dental market doubles annually. With professionals from various fields, its exceptional technologies as well as product competitiveness, the company solidified its position as a global industry leader within a year of being listed. Through digital innovation, it has redefined the dental healthcare experience.

2. Flashforge as the Solution Provider:

Flashforge, a 3D printing software solution provider, offers highly personalized solutions to customers through its multi-field expertise, ongoing innovative technologies, comprehensive and flexible offerings, and top-quality support services. Its user-friendly interface and good user experience enable efficient utilization of different functions, while exceptional technical support further ensures their success. No matter what industry customers are in, Flashforge meets their needs with its innovative and diversified solutions, helping customers stand out in a highly competitive market.

Innovative Technology Integration:

1. Intraoral Scanning Technology:

Medit's intraoral scanning technology finds widespread application in orthodontics, implant, restoration, education, and research, etc. Renowned for its exceptional precision and high resolution, it captures intricate oral structures and teeth details, supporting precise diagnosis and treatment. Medit's technology boasts swift scan speeds for efficient scan completion, enhancing the productivity of dentists and technicians. With intelligent recognition and alignment, it can automatically identify the position of the scanned object, streamlining workflows and improving accuracy. Notably, Medit's scan software features a user-friendly interface, enabling easy operation, design, and analysis for dentists and technicians. Its openness supports various file formats and data imports, facilitating integration with other software and devices.

2. Benefits of Printing Software:

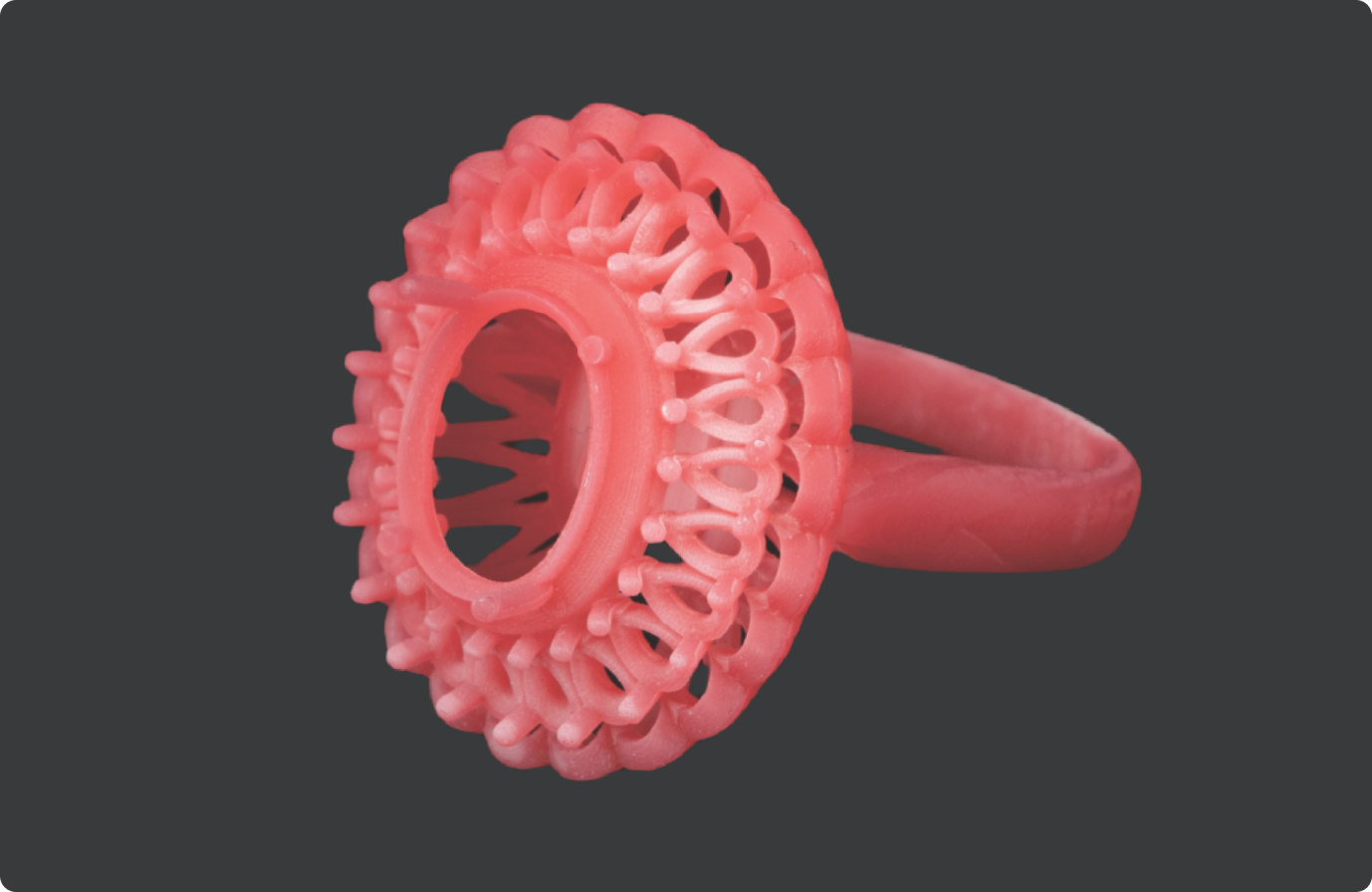

During traditional manufacturing, medical workers shall undergo complex and time-consuming processes, including impression-creating (using impression materials to copy oral structures), impression-taking (sending to dental laboratories), denture fabricating, trial fitting and adjusting, finalizing design, and final production. However, through digital technology, medical workers can directly use intraoral scanners to scan the mouth and process data via the software, generating a digital 3D model of the patient's oral cavity. A designed denture model is then sent to a 3D printer, enabling a more precise and efficient production process. In this collaboration, Flashforge and Medit, a well-known oral scanning brand, have brought users a novel experience in the digital dentistry, enhancing practical application scenarios.

3. Seamless Integration:

Medit seamlessly integrates its intraoral scanning software with Flashforge's slicing software. Now, users can directly access Flashforge's slicing software within Medit's intraoral scanning software after completing oral scans. This means dentists can complete data capture, design, and launch the slicing software within the same interface, streamlining the entire 3D printing process without toggling between multiple software or intricate data conversions. The integration of intraoral scanning and 3D printing brings higher efficiency and convenience to the dental industry, allowing medical workers to focus more on diagnosis and treatment. Also, this helps reduce errors and enhances work precision and quality.

Industry Impact and Future Outlook:

Collaboration Impact:

- Personalized Medical Experience: Digital manufacturing empowers dentists to precisely tailor tooth restorations to each patient's unique needs, enhancing comfort and treatment outcomes.

- Production Efficiency Boost: The digital manufacturing process through the Medit-Flashforge collaboration increases production efficiency. Directly generating and printing digital models streamlines manufacturing steps, reducing human errors and enhancing product consistency and efficiency.

Future Collaboration:

- Enhanced Product Solutions: The Medit-Flashforge collaboration inspires consideration of developing compatible equipment, software and other tools for various diagnosis and treatment phases, so as to provide more comprehensive solutions in the dental field.

- Technical Exchange and Sharing: Deeper technical exchange and sharing will result from the Medit-Flashforge collaboration. This not only accelerates technological innovation but also facilitates mutual learning, improving technical strength and market competitiveness.

Conclusion:

In the digital era, integration and collaboration among diverse technologies become vital for driving innovation. The partnership between Flashforge and Medit presents an inspiring case, encouraging us to bring more convenience and forward-looking solutions to various sectors.