[Case Study] Enabling feasible production of Custom Animal Prosthetics

Introduction

DECAP R&D is passionate about creating the next generation of protective, supportive and companion devices in healthcare, research, veterinary fields. Their expert team of engineers, designers, research and clinical scientists have more than 50 years of combined experience in medical device design, user testing and regulatory requirements. Recently, Decap R&D has partnered with 3BA printing to create personalized and customized prosthetics for animals. Using the Speedy Guider 3 Plus to prototype, and the more capable Creator 4 for finalized versions, 3BA and DECAP have access to some of the finest FDM solutions on the market, which affords them numerous advantages.

Figure . Guider 3 plus printing two halves of a prosthetic prototype using Flashforge PLA

Traditional Manufacturing Methods and Lead Times

Traditional manufacturing methods would have required 3BA and DECAP to use plaster casting to achieve a similar level of customized products that take into consideration the individual needs of every animal. A casting mold is created by using plaster bandages to wrap around the affected part of the body. This is called the negative mold. The negative mold must then be made into a positive mold, by pouring a rapidly solidifying liquid, such as plaster, into the negative mold. Finally, vacuum forming is used to wrap around the positive mold. The vacuum sheet can then be trimmed and cut cleanly, leaving just the bits that are needed for molding. This is a long, resource-intensive process that can take weeks. Alternatively, prefabricated designs that would not offer customizability and a poor fit for patients would have to be used. Customizability of prosthetics is also noted as being one of the most important characteristics for long-term patient satisfaction in both animals and humans.

3D printing also allows for rapid prototyping, meaning that multiple prototypes can be made in quick succession, until the perfect design is achieved. What could take weeks or months can be achieved in mere hours or days using industrial 3D printers such as the Speedy Guider 3 Plus and Creator 4.

Use of Guider 3 Plus

The Guider 3 plus has the fastest single head print speed of all Flashforge printers. With a standard print speed of near 100mm/s, and an ultra-stable frame, the guider 3 plus allows 3BA to create rapid PLA prototypes that are used to test fit after a model is made from 3D scanning. Furthermore, the excellent cooling makes supports easy to remove, even though it is a single extrusion device. This is reflected in the settings visible below. Though the base print speed is 100mm/s, there was no form of layer-splitting, layer shifting, or any other defect in the model. Furthermore, though faster print speeds result in a lower amount of time cooling, the auto-generated supports were easy to remove. There was almost no visible stringing, due to the powerful direct-drive set-up, that only requires 0.8mm distance on the retraction.

Figure The thick Z-rods on the guider 3 plus allow for stability during printing.

Use of Creator 4

For 3BA, adopting the Creator 4 was an excellent decision. It allows us to offer faster lead times, higher reliability in terms of print success rate, and tolerance gaurantees (+/- 0.2mm), and more material options, due to the 3 unique print heads. In the case of DECAP R&D’s joint project for animal prosthetics, the Creator 4 allows for the production of complex prosthetics and high print quality. Furthermore, the low failure rate of parts reduces waste, which aligns with DECAP’s environmentally friendly approach to business.

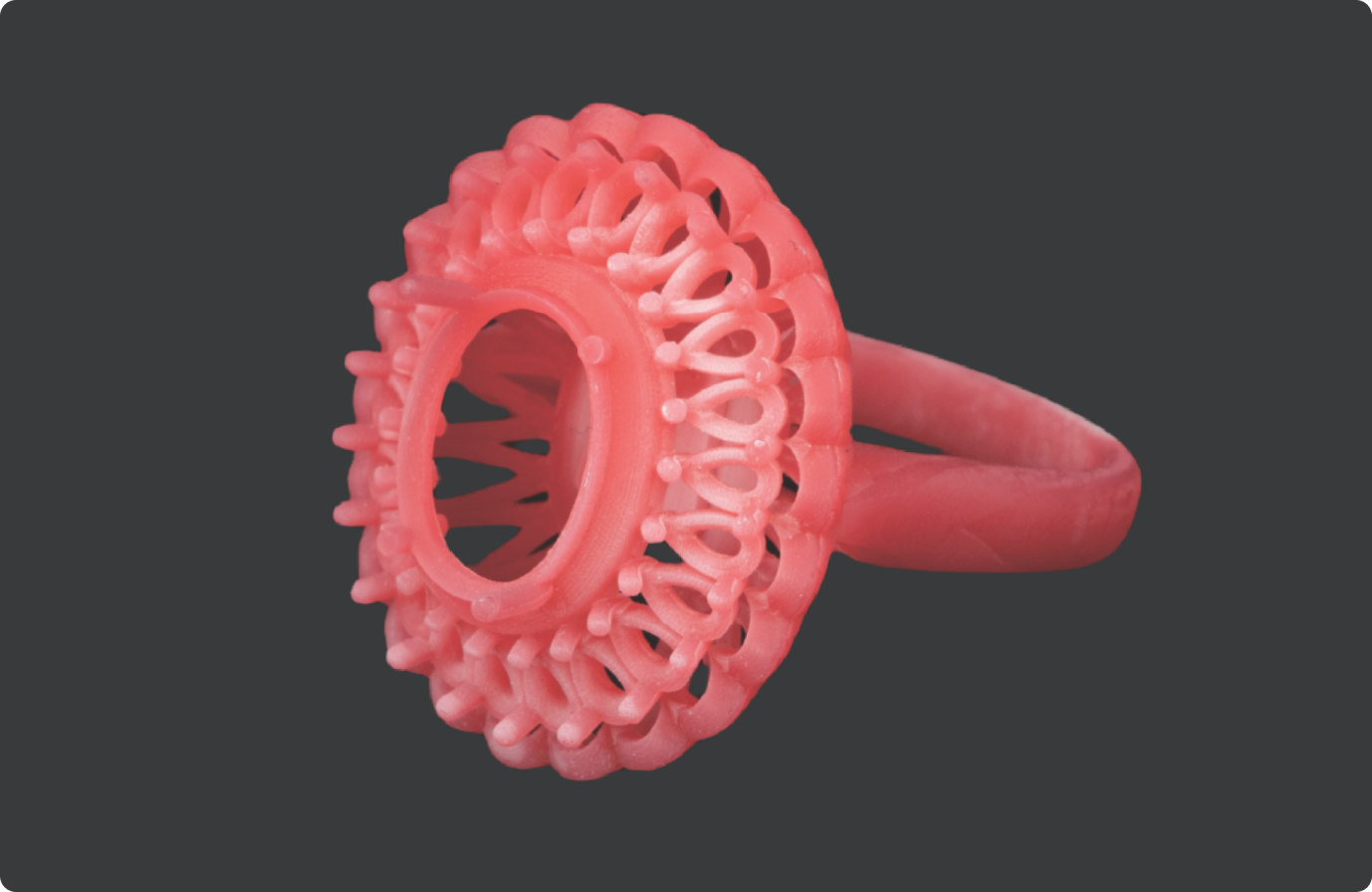

Lastly, some prosthetics require mirrored components, or components with multiple materials in one print, something that the 3 unique print heads and IDEX system of the Creator 4 enables 3BA to offer. For example, some models require complex supported TPU prints. TPU is not a good support material for itself, due to its flexible nature, and thus, the second print-head allows for a second material, such as HIPS to be used as a support material.

Furthermore, the Creator 4 is being used to create slightly larger prototypes, as its overall build volume of 400 x 350 x 500 mm is larger than the Guider 3 plus’s volume of 300 x 300 x 600 mm.