Application of 3D Printing In Personalized Medicine: Making Patient-Specific Implants

Personalized medicine is also called precision medicine, the core of which is patient-specific medical treatment. 3D printing technology can be and will widely be used in personalized medicine due to its nature of custom production. Each person has his individualized body size. Personalized medicine means the healthcare treatment is precisely tailored to individual patient's body needs and requirements. 3D printing allows the creation of objects with unique shapes and sizes that can be well applied in the production procedure of personalized body implants.

A mature application of 3D printing in personalized medicine is in making orthopedics knee joint implants for patients who have knee arthritics pains and plan to replace the broken original knee joint with a new fake one.

▲Human's Knee joint illness

▲Human original knee joint (Left) ; Knee implants after replacement (Right)

How 3D printers help in making body implants?

3D printing in personalized medicine. How 3D printing technology enables the creation of personalized implants? Such 3D printers are capable of creating individualized wax models of body implants, which models are the starter for the following procedure of investment casting (a method to produce real metal bod implants). Know more about How Investment Casting Benefits from 3D Printing Technology.

About how knee implants are made, here is a comparison between in traditional way and in 3D printing way.

In traditional way:

1. Many steps of manually making a knee sample;

2. Getting a generic knee wax model;

3. Casting and molding with the generic wax model;

4. Finishing metal implants of the generic sizes/shapes;

5. Cutting the patient’s femoral bone to fit the implants;

6. Poor implant fit may lead to patient pain after surgical operation.

In 3D printing way:

1. Taking CT scan of the patient’s knee;

2. Based on CT scans to get the patient-specific digital knee model;

3. Using 3D printers to print wax keen models;

4. Molding and casting with the personalized wax models;

5. Final individualized metal implants fit for patient's bone curvature.

6. Good bone coverage; reducing stiffness and patient pains.

Personalized wax models enable the finally-made real knee implants to be precisely fit for the patient’s leg bone. 3D printing used in personalized medicine, patients don’t have to worry about the implant being too large or too small.

See a real 3D printing case in a Chinese medical company

In early June, 2023, a Chinese medical company, located in Suzhou city, contacted Flashforge and made their demands on quick production of wax knee models. By utilizing specific 3D printing technology, Flashforge helped the medical device company 3D printed 6 pieces of individualized wax knee implants.

1. Staff from Flashforge service center imported the knee models to 3D printer software.

▲6 digital models of patient-specific knee implants

2. Flashforge staff 3D printed those models by the usage of the Flashforge Wax 3D printer - WaxJet 400.

▲ 3D printouts: 6 individualized wax knee implants

3. Investing and casting with the 3D printed wax model as the starter.

3D printing in personalized medicine. As soon as getting the wax models, this company then proceeded with the investment casting process, completing making metal knee implants just in a few days, shortening the expected time period by a whole week.

▲Preparation for investment casting ▲Finally: A real metal knee implant

4. Below is the illustration on how the metal knee implant was installed on the patient’s femoral bone.

▲The final product is good in usage test

Advantages of 3d printing for making personalized implants

For medical device companies who are delving themselves into providing precise medicine devices,

1. 3D printing technology enables them to individually manufacture medical devices;

2. Individually manufactured devices are precisely fit for patients, hence less after-surgery complication;

3. 3D printing helps in cutting time and cost on device production;

4. 3D printing reduces waste and human errors, improving production efficiency and quality stability.

5. 3D printing process can be online monitored and adjusted, enhancing production flexibility and controllability.

The 3D Printer Available for Personalized Medicine

The WaxJet 400 is a groundbreaking wax 3D printer specifically designed to cater to the demands of personalized medicine, particularly in the realm of orthopedics. This cutting-edge 3D printer utilizes advanced technology to rapidly produce highly accurate and detailed wax models of implants for knees, hips, spines, or even skulls.

▲ Flashforge Wax 3D Printer - WaxJet 400

These models are utilized by medical professionals to better understand a patient's unique anatomical structure and plan for personalized treatment options. With its speed, precision, and material flexibility, WaxJet 400 3D printer offers an efficient solution for quickly producing highly accurate wax models, empowering medical professionals to advance orthopedic treatments and improve patient outcomes.

Medical companies all around the world, if you are interested in applying such wax 3D printers into the production of personalized medical device please take no hesitation to contact us. Our service team will offer more useful information with greatest warm. Go on reading to get a general understanding of Flashforge wax 3D printer - WaxJet 400.

Feeding with wax material

3D printing for patient-specific implant models uses specific materials. The Flashforge WaxJet 400 uses a unique wax material as its feeding material, which is specifically developed by Flashforge ensuring high precision and smooth surface finishes of the printed models.

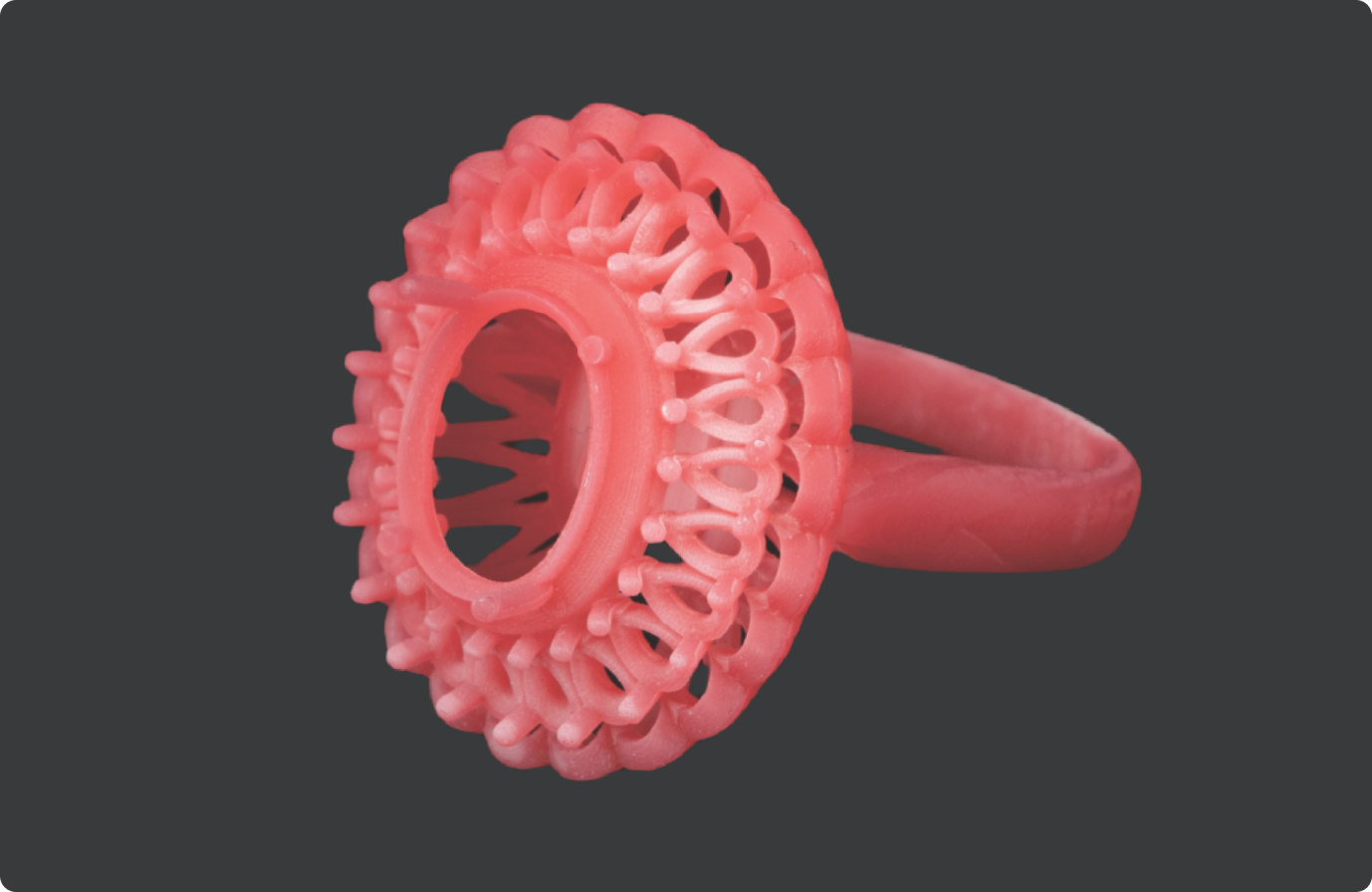

▲3D printed with Flashforge blue wax material

High-precision 3D printing

High-precision 3D printing: The WaxJet 400 is designed to deliver exceptional details. It boasts a dimensional accuracy of ±0.04mm/20mm, enabling the 3D production of personalized intricate models in orthopedics, dentistry, fashion luxuries, and industrial parts.

User friendly

User-Friendly Interface: The wax 3D printer for personalized medicine features an intuitive interface that simplifies the printing process, making it accessible even to users who have not any 3D printing experience.

Fast 3D printing

Flashforge WaxJet 400, with 3 print heads equipped and working simultaneously, triples your printing speed! That means the wax model printing time can be shortened a lot!

In a nutshell

Flashforge 3D printers are capable of creating individualized wax models of body implants for patients. The 3D printed wax models, with precisely personalized shape and size, enables finally-made medical devices precisely fit for end patients! This is how 3D printing is used in personalized medicine.