Flashforge Wax 3d Printer Series

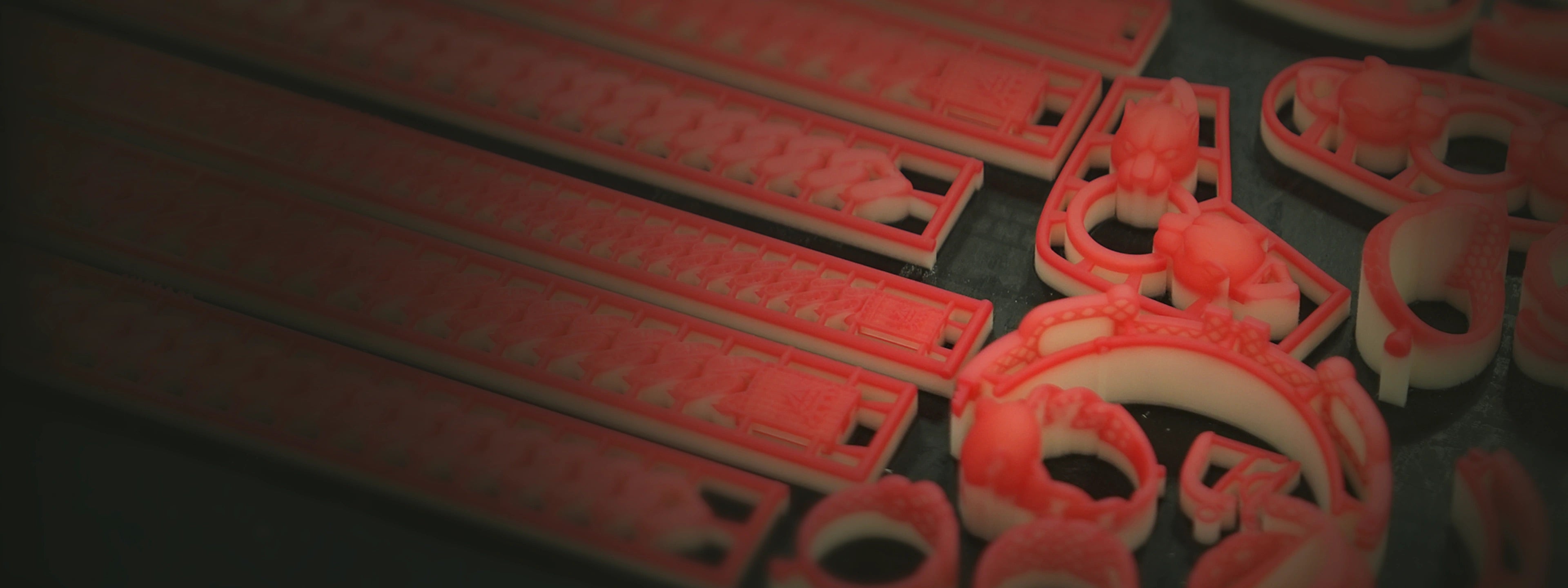

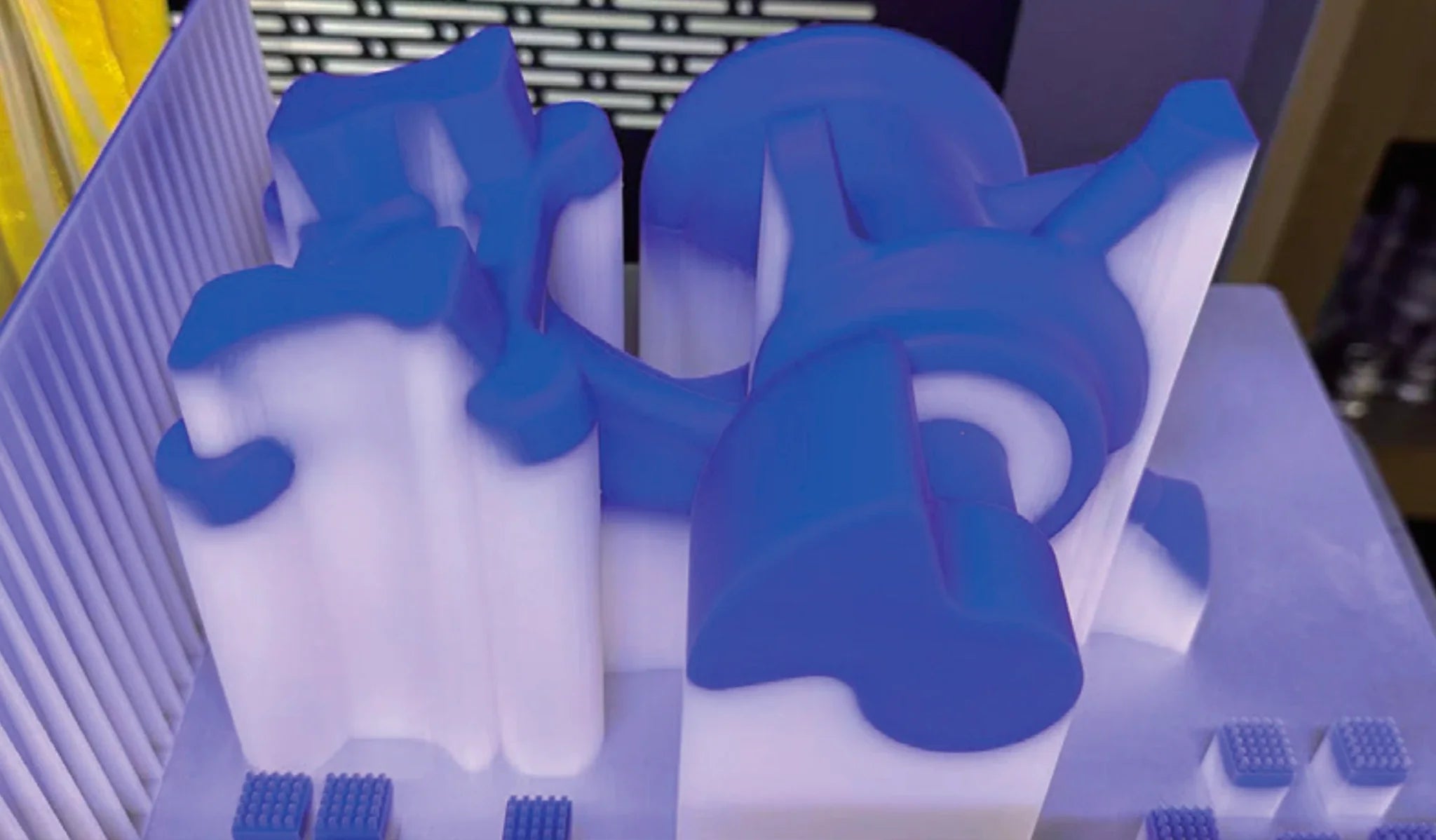

Wax 3D Printers for Jewelry Casting

WJ 530

- Higher Printing Capacity

- 2900x2900x1700 DPI Ultra–High Print Precision

- Top Printing Speed of 6.35mm/h

WaxJet 510

- 2900*2900*1700 DPI

- 15μm per layer

- Lower costs

WaxJet 400

Blogs

Have a question ?

Just leave us a message

Check out the most common questions our customers asked. Still have questions ? Leave us a message — we'll get back to you within 24 hours!

What's the differences between WJ530 and WaxJet 510 3d printer?

- Core Similarities

- Print resolution & layer thicknessBoth models deliver ultra-fine quality: 2900 × 2900 × 1700 DPI, with a 15 µm layer thickness

- Dimensional accuracy±0.04 mm over 20 mm—ideal for intricate jewelry components

- Flashforge WJ530 and WaxJet 510 are both high-precision MJP (MultiJet Printing) wax 3D printers tailored for jewelry manufacturing, but they differ significantly in performance and features:

- The WJ530 features a three-synchronized printhead setup, enabling significantly faster printing speeds compared to the WaxJet 510's single-head system.

- With speeds up to 6.35 mm/h, the WJ530 is approximately 25–50% faster than the WaxJet 510, which typically prints at 4–5 mm/h.

- The WJ530 supports a monthly output of around 12 kg of wax models, making it more suitable for high-volume production environments, while the WaxJet 510 is more geared toward lower-volume runs.

- Thanks to its improved wax circulation system, the WJ530 achieves a material utilization rate of 58–60%, reducing waste and lowering per-model cost. In contrast, the WaxJet 510’s yield is around 40–45%.

- Build Volume: The WJ530 offers a larger build volume of 289 × 208 × 150 mm, suitable for higher throughput and printing more models per batch. In contrast, the WaxJet 510 has a smaller build area of 289 × 208 × 100 mm, making it more appropriate for smaller production runs.

- The WJ530 includes Wi-Fi connectivity and a built-in 2K HD camera for real-time remote monitoring—features not available on the WaxJet 510.

- The WJ530 is equipped with auto-repair algorithms and next-generation wax circulation systems, further optimizing workflow and reliability, while the WaxJet 510 maintains standard print control systems.

What are the key selling points of the WJ530?

The WJ530’s core selling points lie in its high-speed printing, high throughput, superior material efficiency, and smart operation system. Equipped with a triple synchronized printhead setup, it significantly boosts print speed while maintaining fine detail and dimensional accuracy—ideal for large-batch production.

Its built-in 2K HD camera and Wi-Fi connectivity enable real-time remote monitoring, making it easier to manage production remotely and reduce downtime. Additionally, the high wax utilization rate minimizes material waste and lowers operating costs. These features make the WJ530 especially suitable for mid-to-large scale jewelry manufacturers or 3D printing service providers seeking speed, precision, and cost-effectiveness.

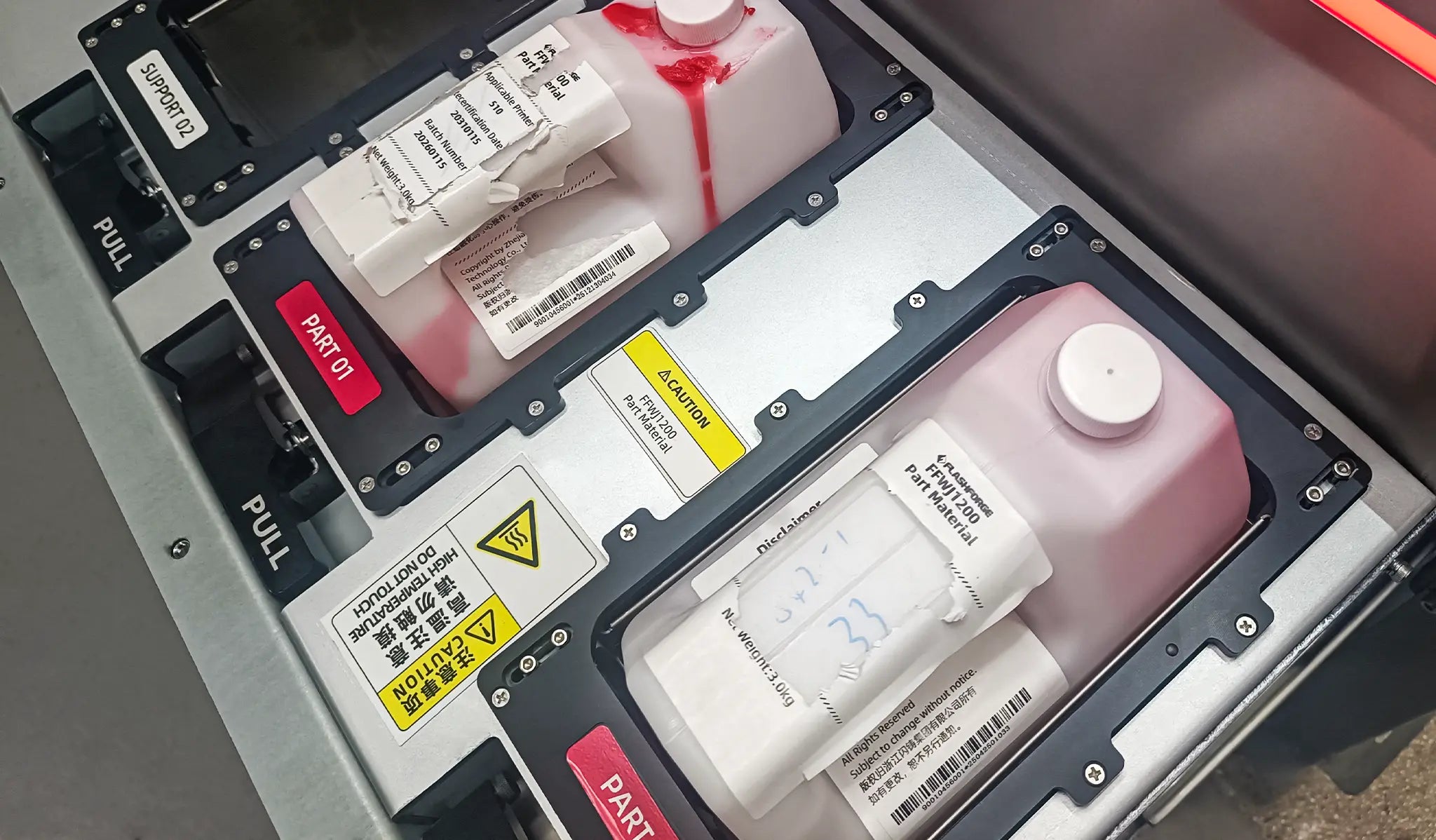

What wax materials does the WJ530 use, and are they compatible with the WaxJet 510?

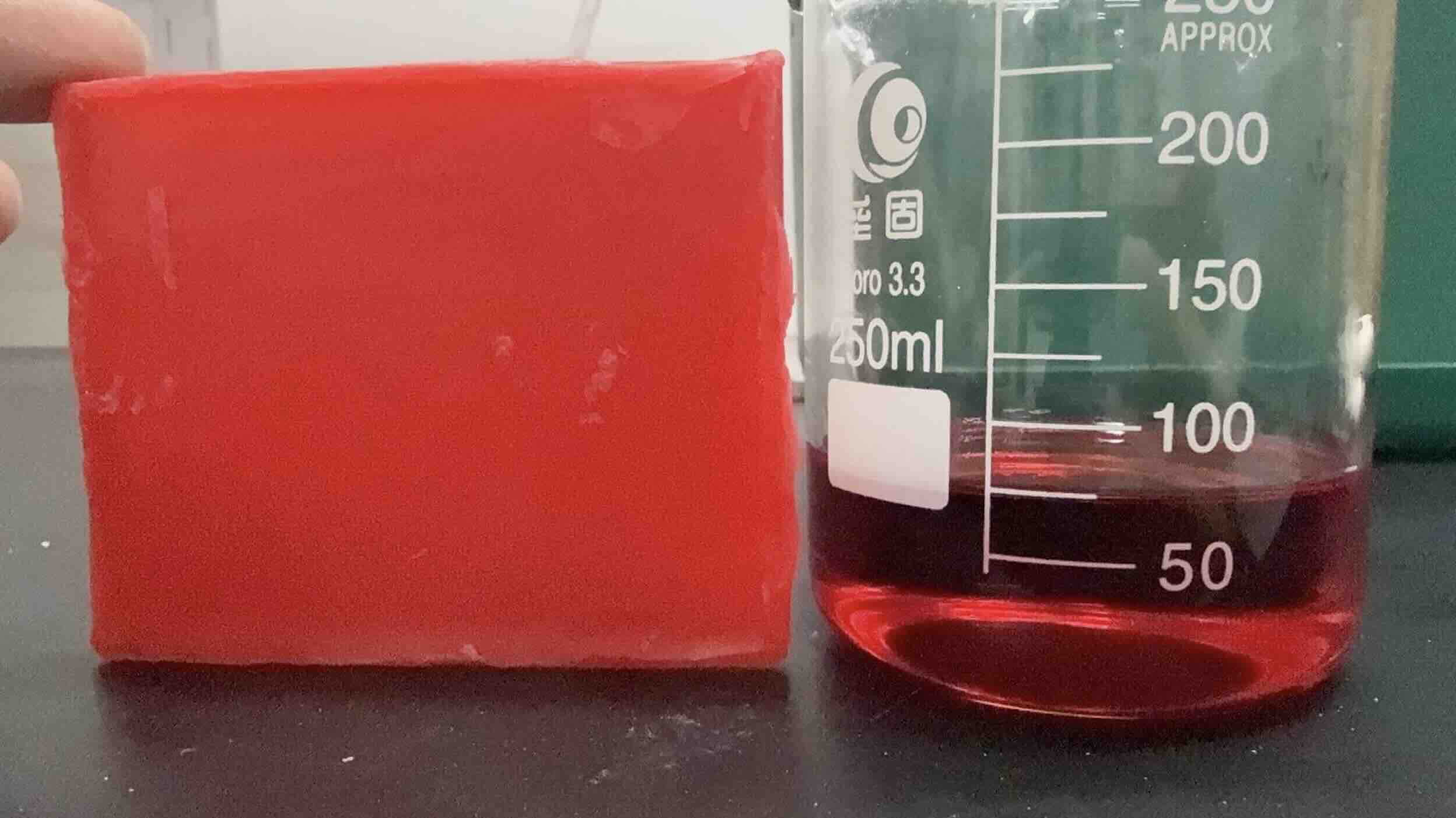

The WJ530 uses red wax as the model material and white wax as the support material. The red wax used in the WJ530 is specially formulated by Flashforge to offer greater toughness and flexibility, making it more suitable for complex or delicate jewelry designs that require higher durability during handling and post-processing.

In contrast, the WJ510 uses purple wax as the model material and the white wax for support. The purple wax is optimized for high precision and smooth surface finish but is less flexible than the red wax used in the WJ530.

Because of the differences in wax formulations—particularly in model materials—the wax materials between the WJ530 and WJ510 are not cross-compatible. Each printer requires its designated wax to ensure proper jetting performance, material behavior, and casting results.

What is the mass production capacity of the WJ530 for wax mode printing?

When running continuously 24/7 for 30 days, a single WJ530 can produce 10–12 kilograms of red wax models per month.

What is the printing resolution and build size of the WJ530?

The WJ530 offers an ultra-high printing resolution of 2900 × 2900 × 1700 DPI with a minimum layer thickness of 15 microns. The maximum build size is 289 × 208 × 150 mm.

What is the price of the Flashforge WaxJet 510 and the WJ530 wax 3D printer?

Thank you for your interest in Flashforge Wax 3d printer. As the global official website of Flashforge, we do not publicly list prices because they may vary by region due to our network of local distributors. However, you’re welcome to leave us a message or inquiry—our professional sales team will get back to you within 24 hours to provide pricing and further assistance.

In the jewelry casting workflow, at which stage does a wax 3D printer help achieve digitalization?

The 3D wax printer for casting enables digitalization at the critical wax pattern production stage, transforming the traditional lost-wax casting workflow into a fully digital process. Jewelers design pieces using CAD software, then use the 3D printer for jewellery making to directly produce wax patterns with exceptional precision and surface quality. This approach—known as 3D wax printing for jewelry—eliminates manual carving and mold-making, speeds up prototyping, allows for intricate geometry, ensures clean burnout, and supports efficient iteration with consistent batch-quality

For jewelry casting, which 3D printing technology is better—resin 3D printing or wax 3D printing?

Wax 3D printing is generally preferred for jewelry casting because it delivers clean burnout, no ash, and consistent results—ideal for mass production. Resin printing, using a jewelry casting resin 3D printer, offers excellent detail and fast prototyping but may require careful burnout schedules to avoid residue. Wax is best for precision casting; resin is great for rapid design iteration.

Can a 3D printer print wax?

Yes, a 3D printer can print wax, but it requires specialized machines known as wax 3D printers. Unlike standard FDM or resin printers, these systems use technologies such as MultiJet Printing (MJP) or Material Jetting to deposit wax materials layer by layer.

Wax 3D printers are mainly used in jewelry casting, dental applications, and precision investment casting, where extremely fine details and smooth surfaces are essential. For example, in jewelry making, printers like the Flashforge WaxJet series can produce high-precision wax models that are later used in the lost-wax casting process, allowing jewelers to create complex designs with clean burnout and minimal material waste.

What is wax 3d printer?

A wax 3D printer is a professional tool for producing detailed wax patterns, mainly for jewelry and precision casting.