Impressora 3D de Cera para Joias: Imprima Moldes Perfeitos

Wax 3D printers are revolutionizing the jewelry industry, offering jewelers a way to create intricate and precise designs with ease. These specialized 3D printers use wax 3D printing technology to produce wax patterns that are then used in the lost wax casting process, enabling the creation of stunning jewelry pieces. Let's dive into the world of wax 3D printers and discover how they can transform your jewelry manufacturing workflow.

Understanding Wax 3D Printers

What is a Wax 3D Printer?

A wax 3D printer is a type of 3D printer specifically designed to print using wax materials. Unlike standard 3D printers that use plastics or resins, these printers use wax to create highly detailed 3D models. The primary use of wax 3D printers is in creating wax patterns for lost wax casting, a traditional method used in jewelry manufacturing. These printers offer exceptional precision and a smooth surface finish, making them ideal for producing intricate jewelry designs.

How Wax 3D Printers Work

Wax 3D printers typically work by layering molten wax material to build a 3D model based on a digital 3D model. The technology behind wax 3D printing ensures each layer is accurately placed, resulting in a high-resolution and precise final product. Some wax printers use a process similar to inkjet printing, where tiny droplets of wax are jetted onto a build platform and solidified layer by layer. Others use a heated print head to extrude wax. Support structures are often used to support the wax patterns during the 3D printing process, particularly for overhanging features. These supports are made of a dissolvable wax material, which can be easily washed away after printing. After the support material is washed away, the wax patterns are ready for the lost wax casting process.

Benefits of Using Wax 3D Printers in Jewelry

Using wax 3D printers in jewelry manufacturing offers several key benefits. Firstly, the precision and resolution of these printers allow for the creation of intricate designs with a smooth surface finish. This is crucial for jewelry, where detail and appearance are paramount. Secondly, wax 3D printing provides a fast and efficient method for producing wax patterns, reducing production time and cost compared to traditional wax carving methods. The ability to quickly prototype and iterate on designs also enhances the design process. Wax 3D printers enable repeatable and accurate results, which is essential for mass production and high-volume production of jewelry. The use of castable wax materials ensures that the final jewelry pieces are of high quality and meet the required specifications.

Flashforge Technology in Wax Printing

Introduction to Flashforge 3D Wax Printers

Flashforge is a well-known name in the world of 3D printing, and their 3D wax printers are gaining popularity in jewelry manufacturing. Flashforge 3D wax printers are designed to produce high-quality wax patterns for lost wax casting with great precision. These printers use specialized wax materials to create intricate 3D models that can be directly used in the casting process. Flashforge wax printers are equipped with advanced 3D printing technology to ensure each layer is accurately built, resulting in a smooth surface finish and repeatable results. This provides an efficient workflow for jewelers looking to enhance their production capabilities.

Specifications of Flashforge Printers

Flashforge 3D wax printers come with a range of specifications that cater to the needs of jewelry designers and manufacturers. These printers typically offer high resolution, allowing for the creation of intricate details in the wax patterns. The build volume is usually designed to accommodate multiple jewelry pieces in a single print job, increasing production efficiency. Flashforge wax printers often support various wax materials, giving users flexibility in choosing the best material for their specific application. The printers also feature user-friendly software for easy 3D model preparation and printing. Overall, the specifications of Flashforge wax printers focus on precision, speed, and quality.

Precision and Quality in Wax Printing

Precision is paramount when creating wax patterns for jewelry, and Flashforge wax printers excel in this area. These printers are engineered to produce wax 3D models with exceptional accuracy, ensuring that the final cast jewelry pieces meet the required specifications. The high resolution of Flashforge wax printers enables the creation of fine details and smooth surfaces, essential for achieving a professional finish. The wax 3D printing technology used by Flashforge minimizes errors and ensures repeatable results, making it a reliable tool for jewelry manufacturing. The combination of precision and quality offered by Flashforge wax printers makes them a valuable investment for jewelry studios and manufacturers.

Printing Process for Jewelry Casts

Creating Wax Patterns for Jewelry

The initial phase in using a 3D wax printer for jewelry involves creating wax patterns. First, a 3D model of the jewelry piece is designed using CAD software. This digital design is then imported into the wax 3D printer's software. The wax 3D printer uses this 3D model as a blueprint to create the wax pattern. The choice of wax materials is crucial at this stage to ensure it has the right properties for casting. Precision in creating these wax patterns directly affects the quality of the final jewelry product, ensuring every detail is accurately reproduced.

Layering Techniques in Wax 3D Printing

Wax 3D printing relies on layering techniques to build the 3D model. The wax 3D printer deposits thin layers of wax material, one on top of another, until the complete wax pattern is formed. The resolution of these layers is a key factor in the surface finish of the final product. Support structures, often made of a dissolvable wax material, are used to support overhanging features during the 3D printing process. Different wax 3D printers employ varying methods of layering, such as material jetting or extrusion, each influencing the speed and precision of the wax 3D printing process. These layering techniques are essential for achieving intricate designs in wax patterns.

Post-Processing and Preparing for Casting

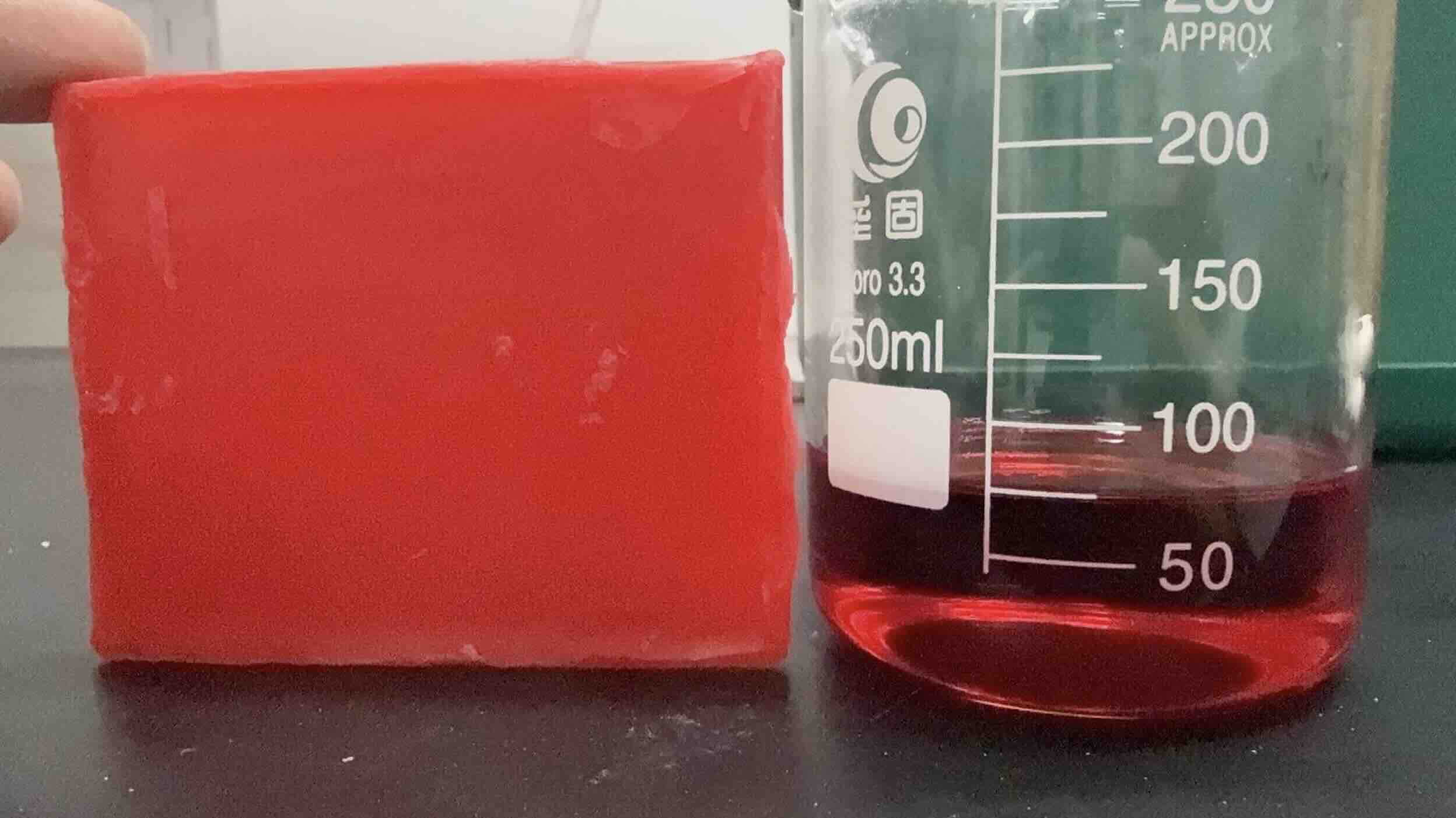

After the wax 3D printing is complete, post-processing is essential to prepare the wax patterns for casting. This typically involves removing support structures and smoothing the surface. Support wax structures are dissolved using a wash solution, leaving behind the final wax pattern. The wax pattern is then carefully inspected for any imperfections and manually refined to ensure a smooth surface. Castable wax material is used, so it’s very important that there is no ash left behind. This preparation is critical for achieving high-quality jewelry casts in the lost wax casting process, and affects the resolution of the final product.

Efficiency and Speed in Production

Comparing Speed and Quality in Wax Printing

When considering wax 3D printing, speed and quality are often weighed against each other. Wax 3D printing speed can increase wax patterns production efficiency, but it may sometimes compromise the surface resolution and precision of the final wax 3D models. Conversely, prioritizing high resolution for a smooth surface finish and more accurate wax 3D prints can lead, but it may also extend the wax 3D printing time. Jewelry manufacturers often need to find a balance between speed and resolution, depending on the complexity of the wax patterns and the volume of production they need to achieve. Wax 3D printers offer high resolution without sacrificing speed, using specialized wax materials and optimized 3D printing techniques.

Mass Production Capabilities of Wax Printers

Wax 3D printers are transforming jewelry manufacturing by enabling efficient mass production of wax patterns. Unlike traditional methods, wax 3D printing allows for repeatable and accurate creation of wax 3D models, making it ideal for high-volume production. With a wax 3D printer, jewelry manufacturers can produce multiple wax patterns simultaneously, significantly reducing production time and costs. The ability to quickly prototype and iterate on designs further enhances production efficiency, allowing for rapid adjustments and improvements. Automated wax 3D printing processes ensure consistent quality and minimize manual intervention, making wax 3D printers an essential tool for scaling up wax production in the jewelry industry.

Cost Efficiency in Jewelry Manufacturing

Investing in wax 3D printing can lead to significant cost savings in jewelry manufacturing. While the initial equipment cost for a wax 3D printer may seem substantial, the long-term benefits can outweigh the investment. Wax 3D printing reduces material waste compared to traditional methods, as wax 3D materials are precisely deposited to create the wax 3D model. The speed and accuracy of wax 3D printing also reduce labor costs, as fewer manual processes are required. By enabling rapid prototyping and iteration, wax 3D printers help to refine designs quickly, reducing the risk of costly errors in final production. This overall efficiency makes wax 3D printing a cost-effective solution for jewelry manufacturers.

Future Trends in Wax 3D Printing for Jewelry

Advancements in Material Technology

The future of wax 3D printing in jewelry manufacturing is closely tied to advancements in material technology. Researchers are continuously developing new wax materials with improved properties such as higher resolution, smoother surface finishes, and enhanced castable resin features. These new wax materials are also being engineered to melt more cleanly during the lost wax casting process, leaving behind less ash and ensuring higher quality final jewelry pieces. Additionally, there is a focus on creating wax materials that are more durable and less prone to cracking or distortion during wax 3D printing, further improving the efficiency and reliability of the wax 3D printing process.

Emerging Techniques in Wax Printing

Emerging techniques in wax 3D printing are set to revolutionize the jewelry industry. One such technique involves multi-material wax 3D printing, where different wax materials with varying properties are used within the same wax 3D model. This allows for greater design flexibility and the creation of more complex jewelry pieces. Another promising trend is the integration of AI and machine learning into the wax 3D printing process, enabling automated optimization of 3D printing parameters for improved resolution, speed, and material efficiency. These advancements promise to unlock new possibilities for jewelry designers and manufacturers.

Impact of 3D Printing on Jewelry Design

3D printing, especially wax 3D printing, is having a profound impact on jewelry design, empowering designers to create intricate and innovative pieces that were previously impossible to manufacture. The precision and resolution of wax 3D printers allow for the creation of complex geometries and fine details, pushing the boundaries of traditional jewelry design. Designers can now quickly prototype and iterate on designs, experimenting with new forms and structures with ease. This rapid prototyping capability accelerates the design process and allows for greater creativity and innovation. The use of wax 3D printing also democratizes the jewelry design process, making it more accessible to independent designers and small studios.