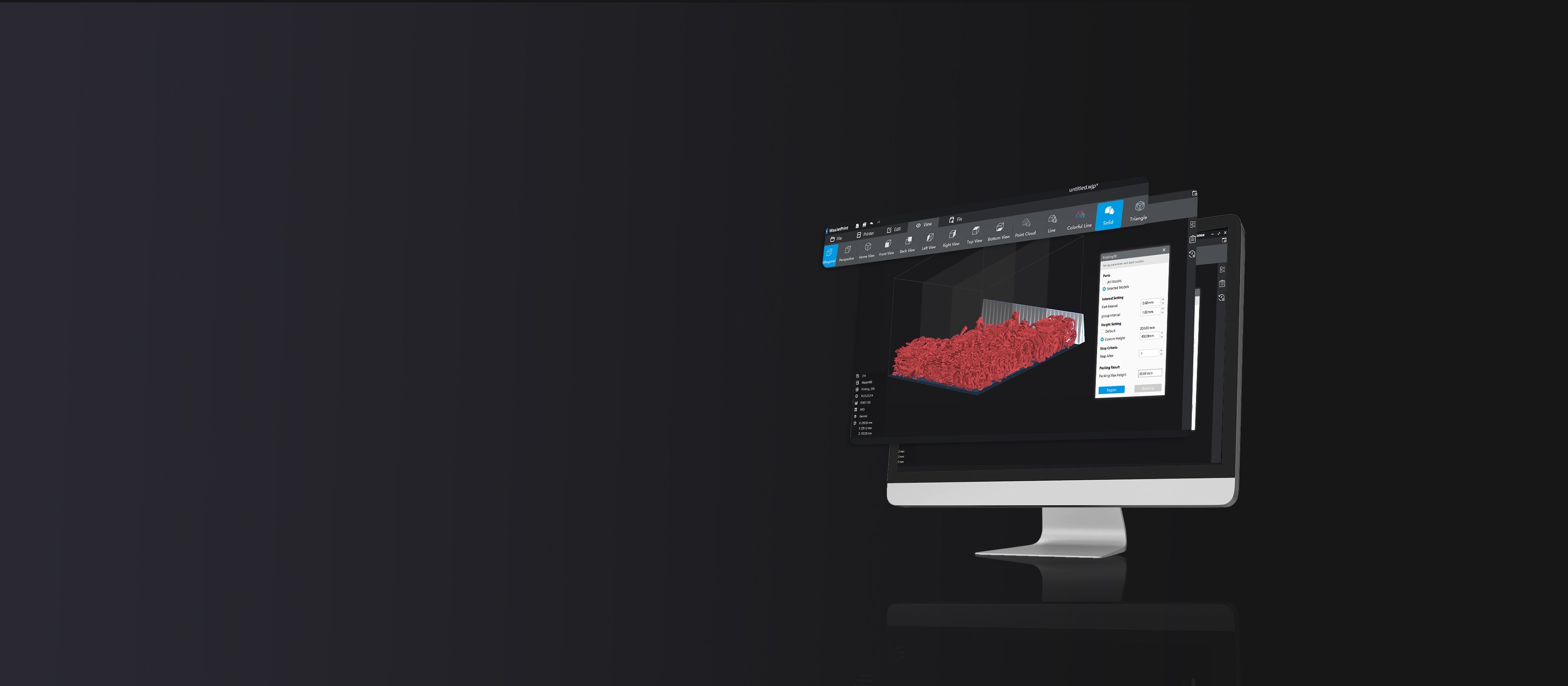

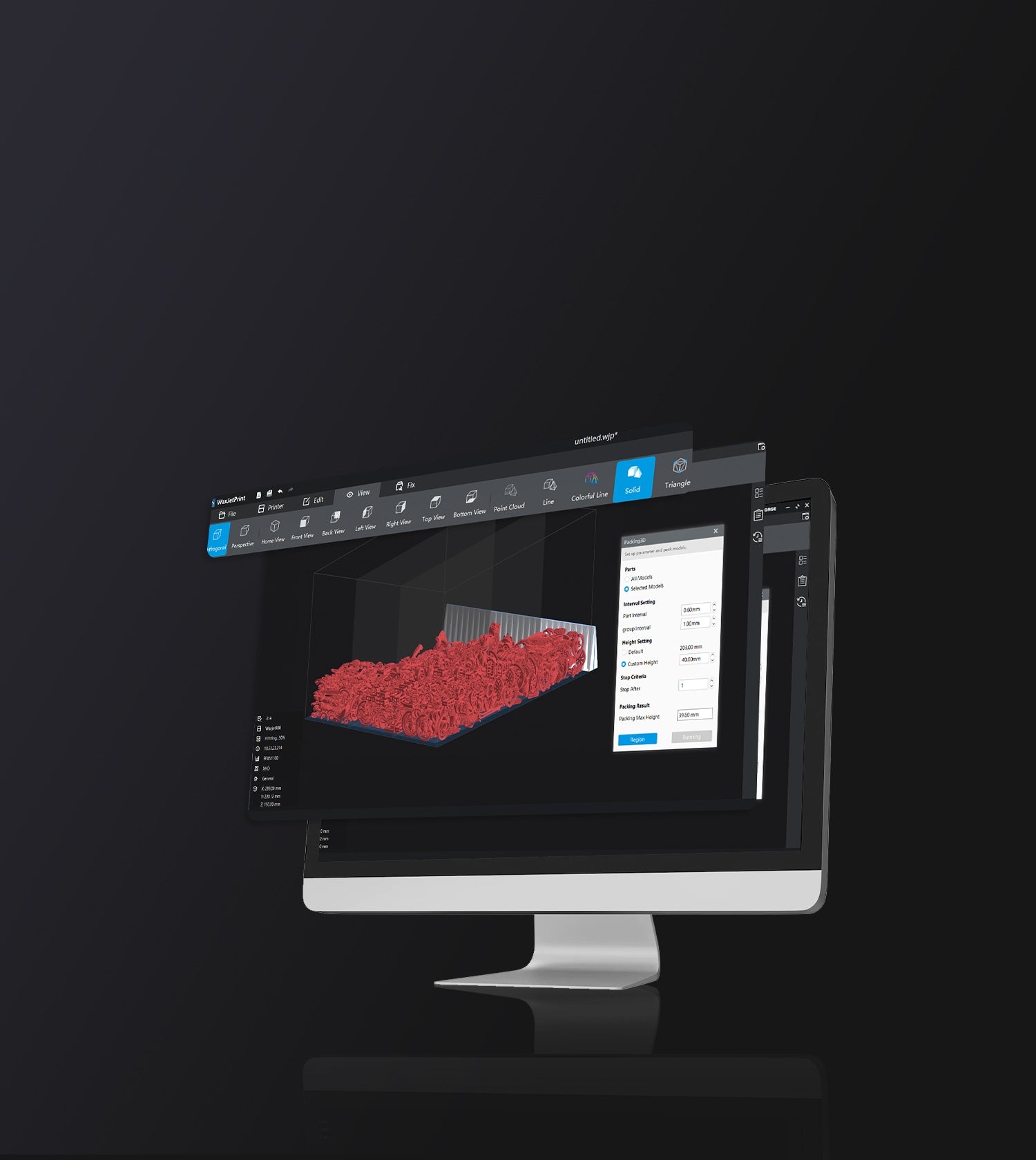

User-Friendly Workflow

24/7 Printing,

Unattended & Continuous

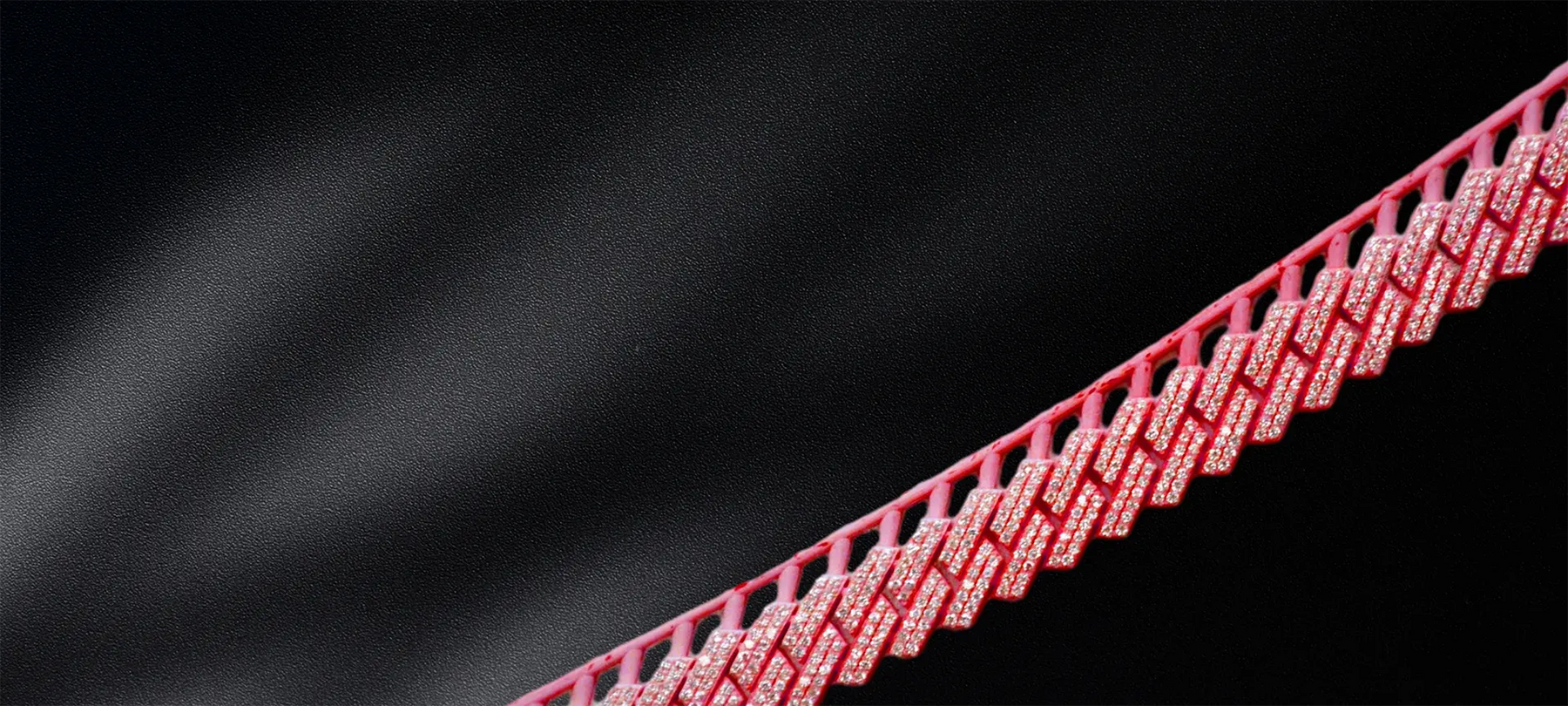

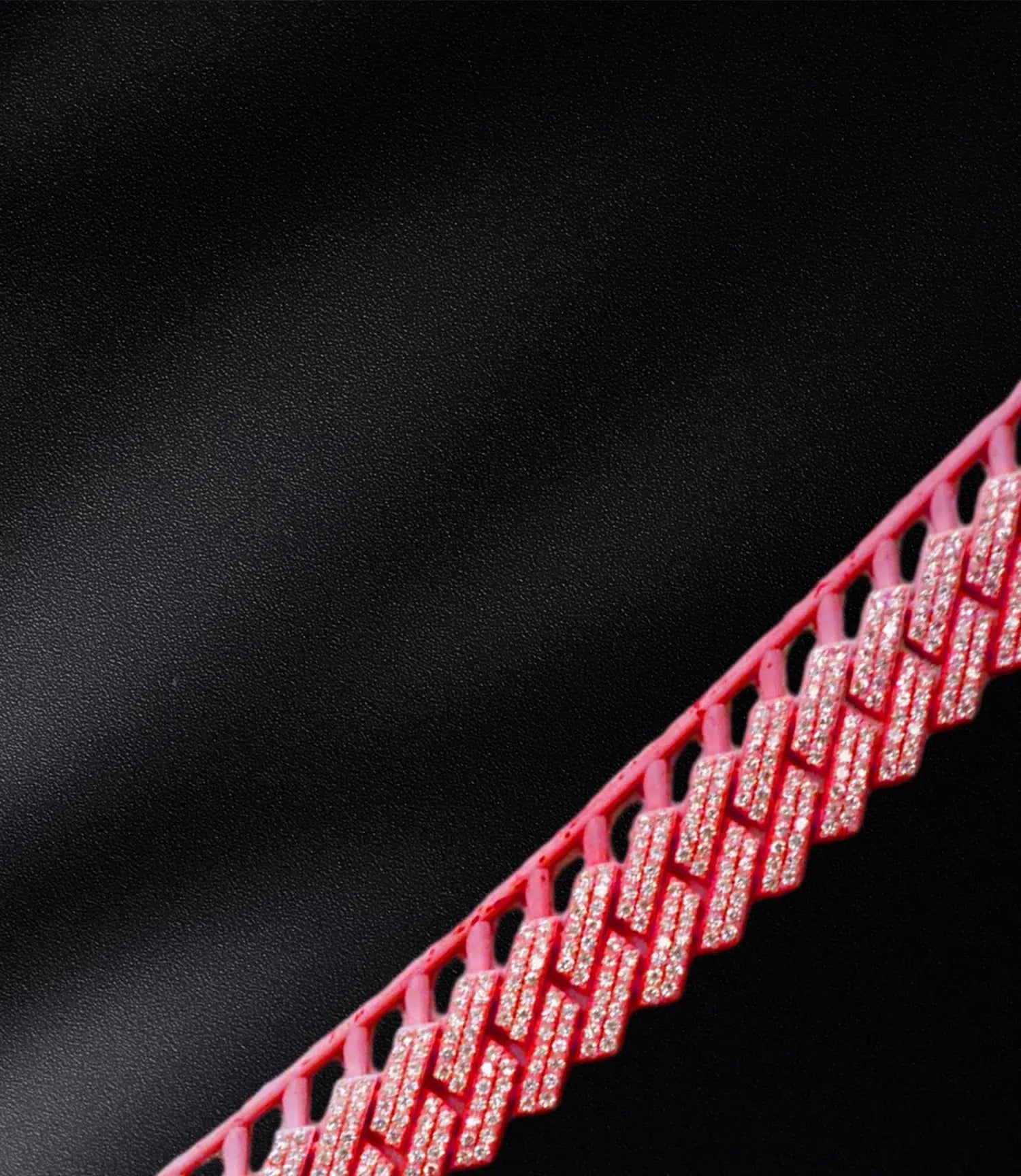

Enhanced Wax, Ideal

for Complex Designs

Contact-Free Support Removal,

Easier Post-Processing

Technical Parameter

Printing Technology

289*208*100mm

XHD:2900*2900*1700 DPI layer thickness:15um

±0.04mm/20mm

AC220-240V,50Hz,4KW

1352*775*1600mm

480kg

630kg

1530*900*1837mm

WaxJetPrint

stl/.slc

√

500G

Network 10/100/1000Ethernet/USB

Windows7/Windows 10(64bit)

Temperature:18-26℃; humidity: 30-70%

Material Specifications

FFWJ1200

FFWJ3200

Part material

Support material

1.5kg/bottle

1.6kg/bottle

100% wax

Wax support materia

Red

White

0.79g/cm°

0.85g/cm

68℃

55℃

63℃

-

1.1%

-

0.7%

-

9

-

<0.01%

-

High-precisioncasting wax materia

Hands-free dissolvable support material

*Conditions: ①Volumetric Shrinkage SH/T 0588-1994; ②Needle Penetration Hardness GB/T 4985-2010; ③Ash Content GB/T 14235.3-1993

Technical Parameter

MultiJet Printing (MJP)

Material Name

FFWJ1200

FFWJ3200

289*208*100mm

Material Type

Part material

Support material

XHD:2900*2900*1700 DPl; layer thickness:15um

Net Weight

1.5kg/bottle

1.6kg/bottle

±0.04mm/20mm

Composition

100% wax

Wax support material

AC220-240v,50hz,4kw

Color

Red

White

1352*775*1600mm

Density@95°C(Liquid)

0.79g/cm³

0.85g/cm³

480kg

Melting Point

68℃

55℃

630kg

Softening Point

63℃

—

1530*900*1837mm

Volumetric Shrinkage

1.1%

—

WaxJetPrint

Linear Shrinkage

0.7%

—

.stl/.slc

Needle PenetrationHardness

9

—

√

Ash Content

<0.01%

—

500g

Description

High-precision castingwax

Hands-free dissolvable

support material

Network 10/100/1000 Ethernet/UsB

Windows7 /Windows 10(64bit)

Temperature:18-26°C; humidity: 30-70%

Have a question ?

Just leave us a message

Check out the most common questions our customers asked. Still have questions ? Leave us a message — we'll get back to you within 24 hours!

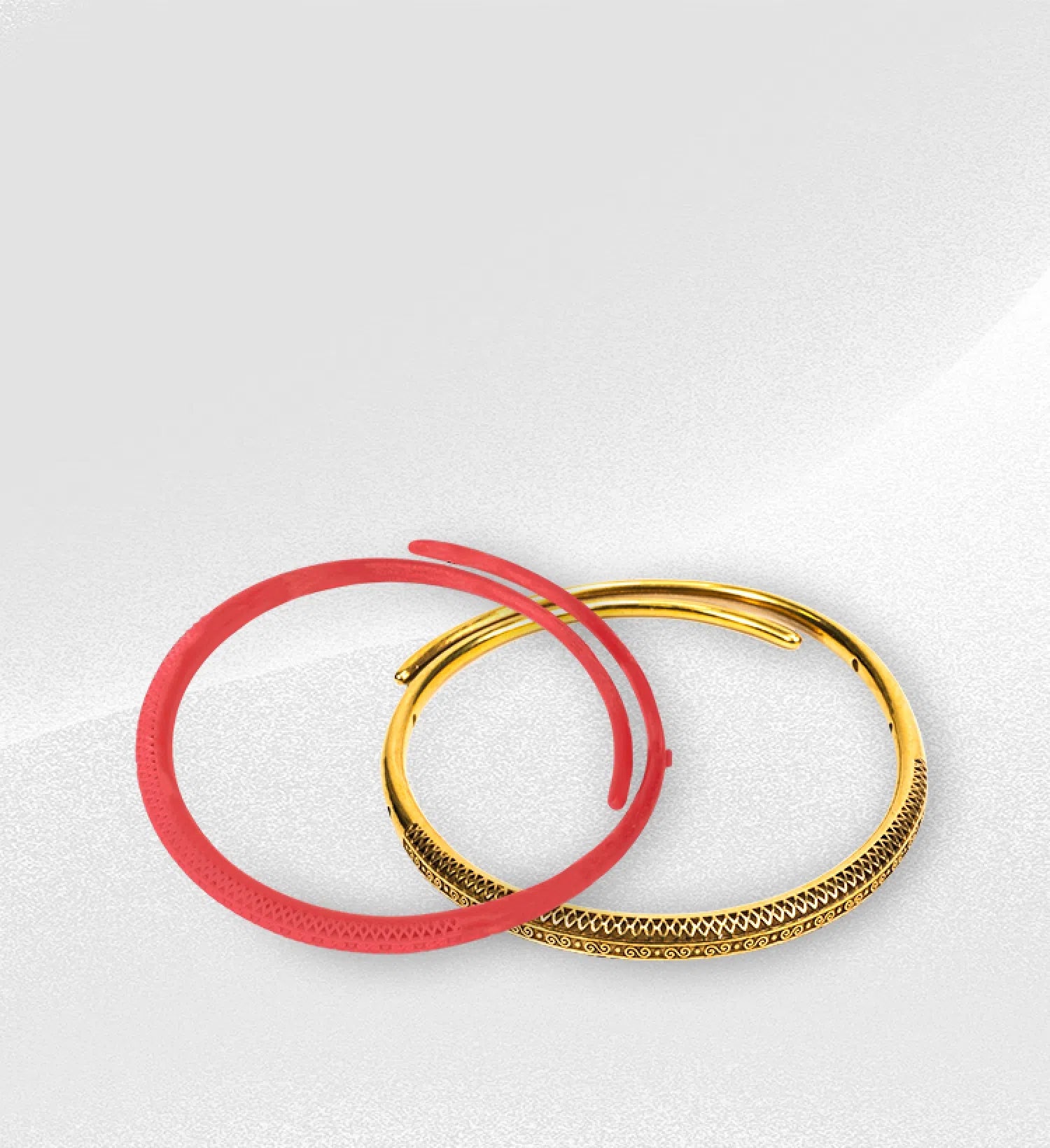

What are the key features and advantages of the Flashforge WaxJet 510 wax 3D printer?

The Flashforge WaxJet 510 is an industrial-grade wax 3D printer designed specifically for high-precision jewelry manufacturing. Its core advantages include:

- Industry-leading 2900×2900×1700 DPI ensures crisp detail, perfect for micro-pavé and filigree designs.

- 15μm minimum layer height enables smooth surfaces and intricate features.

- Dimensional accuracy of ±0.04mm/20mm meets the demands of precision casting.

- 289×208×100 mm printing size supports batch production at industrial scale.

- Ideal for detailed, high-value, and customized wax patterns in gold and silver casting.

- Delivers stable output and consistent results for professional manufacturers.

This makes the WaxJet 510 a top choice for jewelry brands and service providers seeking both quality and efficiency.

Where can I find the price for WaxJet 510?

Flashforge collaborates with regional distributors around the world, so prices may vary by country. To get an accurate quote and product consultation, simply leave us a message—we’ll respond within 24 hours.

What’s the best 3D wax printer for jewelry in 2024–2025?

The Flashforge WaxJet 510 is widely regarded as the top 3D wax printer for jewelry in 2024–2025. It was ranked No.1 in global sales for MJP wax 3D printers in 2024, making it one of the most trusted and popular choices among professional jewelry manufacturers worldwide.

Its ultra-high resolution, precision performance, and large build volume make it ideal for producing high-quality wax models for casting—especially in applications like micro-pavé, filigree, and custom fine jewelry.

How many printheads does the Flashforge WaxJet 510 have?

The Flashforge WaxJet 510 is equipped with one printhead.

What software does the WaxJet 510 use?

The WaxJet 510 uses WaxJetPrint, a proprietary slicing and control software developed by Flashforge specifically for the WaxJet series of 3D printers. It’s designed to optimize print quality, support generation, and workflow efficiency for high-precision wax modeling.

What are the printing resolution and build volume of the WaxJet 510?

The Flashforge WaxJet 510 offers ultra-high resolution of 2900 × 2900 × 1700 DPI, with a minimum layer thickness of 15μm and dimensional accuracy of ±0.04mm/20mm.

Its build volume is 289 × 208 × 100 mm, making it ideal for high-precision, batch jewelry production.