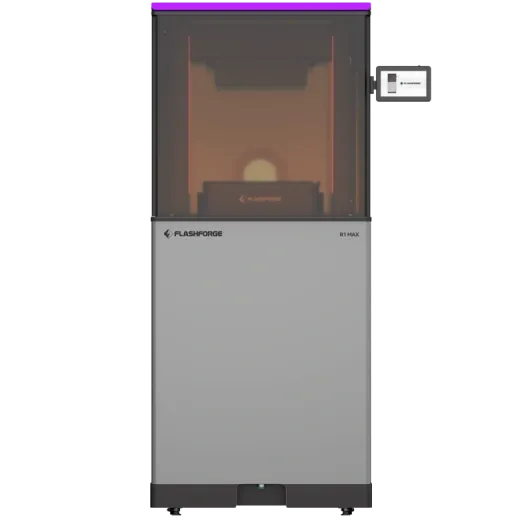

Flashforge's next-gen additive manufacturing solutions leverage 3D printing's mold-free advantage to overcome the hurdles of injection molding, MOQ, and long lead times. This enables zero-mold production, single-piece runs, and rapid response.

Businesses can flexibly iterate and produce on demand during prototyping, trial runs, or small-batch deliveries, significantly reducing costs. Our solutions serve as an ideal upgrade and complement to traditional injection molding.

Mold-Free Production

100% savings on mold costs

Skip the 20-day mold-making cycle

Instant Iteration

No need to remake molds

Adjust and produce on the spot

Rapid Delivery

Ship as fast as the same day

Produce on demand with no inventory pressure

No MOQ Barriers

Break free from MOQ limits

Trial production with zero inventory risk

Mold-Free Production

100% savings on mold costs

Skip the 20-day mold-making cycle

Rapid Delivery

Ship as fast as the same day

Produce on demand with no inventory pressure

No MOQ Barriers

Break free from MOQ limits

Trial production with zero inventory risk

Instant Iteration

No need to remake molds

Adjust and produce on the spot

Let's take a high-precision mold and a three-round design optimization for a creative lampshade as an example.

Traditional Injection Molding

Flashforge RapidMake

Modify your design and produce instantly

For more details, please contact us at info@flashforge.com.

Broad Industry Applications

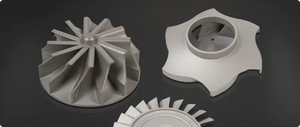

1. Industrial Manufacturing

2. Consumer Electronics & Smart Hardware

3. Medical & Healthcare

4. Cultural & Creative Products

5. Daily Necessities & Cosmetic Packaging

6. Architecture/Education/Research

7. Aerospace & Transportation