Materiales de cera para impresión 3D de joyería: cera roja y blanca explicados

En la industria de fabricación de joyas, las máquinas de impresión 3D en cera han reemplazado gradualmente el tallado manual tradicional en cera y algunos procesos CNC, y se han convertido en una herramienta importante en la producción modernizada. Utilizando tecnología de inyección de alta precisión, las impresoras de cera depositan materiales de cera capa por capa y crean rápidamente modelos de cera con detalles finos y superficies lisas. Luego, estos modelos de cera se utilizan para la fundición a la cera perdida. Como resultado, se producen productos metálicos de alta calidad. En todo el proceso de impresión, los materiales más críticos son la cera roja y la cera blanca.

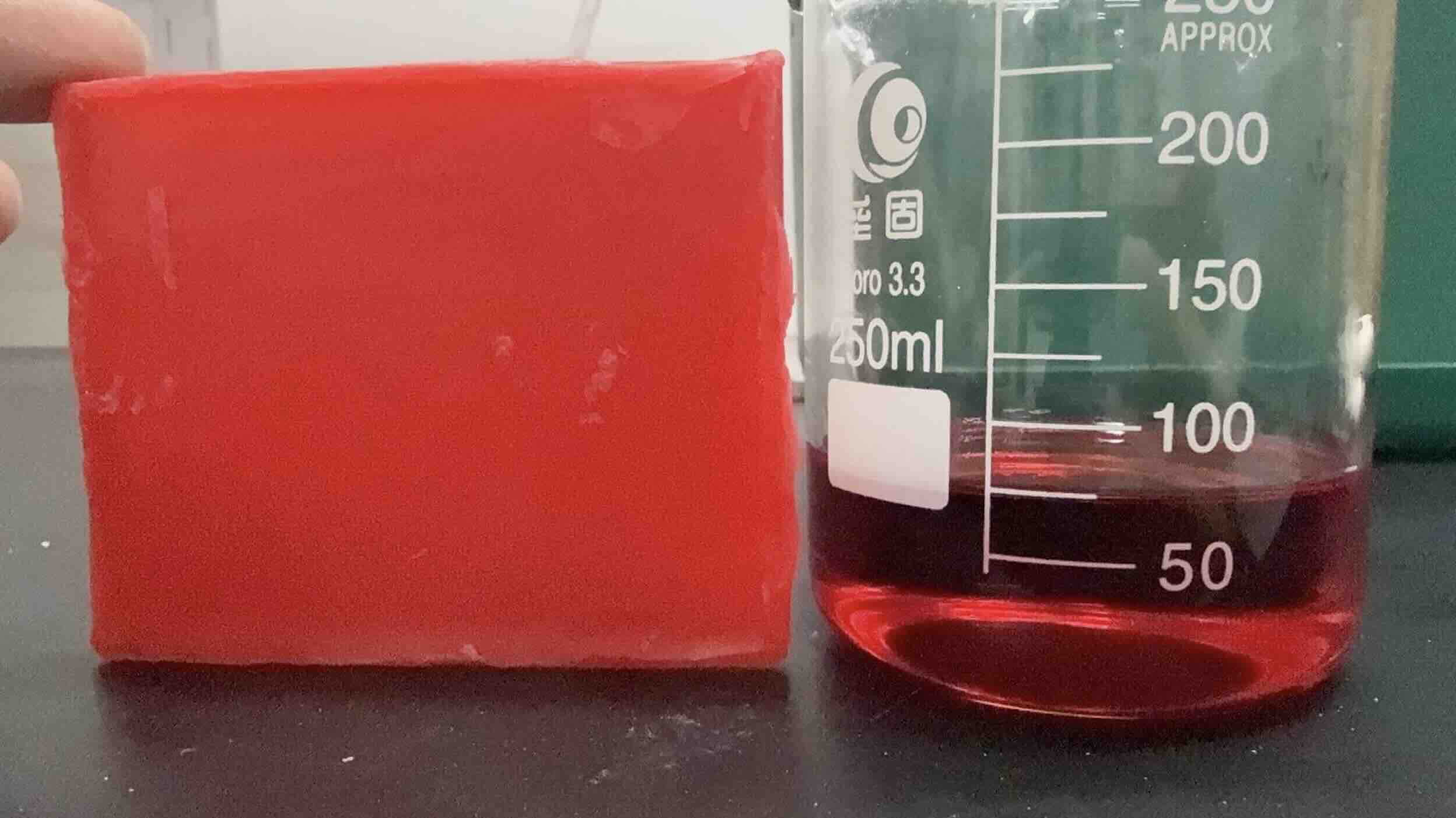

Composición y propiedades de la Cera Roja

La cera roja se utiliza típicamente como el material principal para imprimir el cuerpo principal de los modelos de joyería. Está hecha de una combinación de cera sintética, cera fotosensible y una pequeña cantidad de modificadores de resina. Esta combinación le da a la cera roja suficiente dureza para mantener la estabilidad y mostrar los detalles delicados de las formas impresas durante el proceso de impresión. Más importante aún, durante la fundición a alta temperatura, la cera roja se quema casi completamente limpia y apenas deja residuos. Esta característica garantiza la pureza de la superficie metálica en el proceso de fundición a la cera perdida y previene problemas de calidad como poros o inclusiones. Como resultado, la cera roja se usa ampliamente como material principal para crear joyas con diseños complicados como anillos, pendientes y colgantes en la industria de la joyería. Especialmente para piezas con estructuras intrincadas como calados y filigranas, la cera roja puede reproducir perfectamente la creación de los diseñadores, lo que hace que los productos terminados sean precisos y hermosos.

Funciones y propiedades de la Cera Blanca

En contraste, la cera blanca no se utiliza directamente en el producto terminado, sino que se usa específicamente como material de soporte para ayudar en el proceso de impresión. Su composición típicamente consiste en cera de bajo punto de fusión, y a veces se pueden añadir polímeros solubles en algunas formulaciones, lo que le da una naturaleza suave y fácilmente removible. Durante el proceso de impresión, la cera blanca se forma debajo, dentro de las paredes o alrededor de las partes colgantes del modelo para soportar el modelo principal de cera roja. De esta manera, incluso estructuras altamente complejas o colgantes pueden imprimirse con éxito sin colapsar o deformarse.

Métodos para eliminar el material de soporte

Una vez que su función de soporte ha terminado, la cera blanca debe eliminarse completamente. Este paso se realiza típicamente mediante calentamiento para derretir la cera blanca o disolviéndola con disolventes químicos. Y esto puede asegurar la textura delicada y suave de la superficie del cuerpo principal del modelo.

Cooperación de la cera roja y la cera blanca en la impresión

Los diferentes roles y la cooperación entre la cera roja y la cera blanca forman una combinación muy estable en la impresión 3D de joyería. La cera roja asegura la calidad y la capacidad de fundición del modelo de cera, mientras que la cera blanca asegura la estabilidad estructural y la precisión durante la impresión. Debe notarse que la adhesión entre la cera roja y la cera blanca está cuidadosamente diseñada: durante la impresión, es lo suficientemente fuerte para soportar el modelo, pero no tan fuerte como para que la cera roja y blanca sean difíciles de separar. Este equilibrio es importante para una impresión de cera exitosa y fluida.

Condiciones de almacenamiento para materiales de cera

Tanto la cera roja como la cera blanca tienen requisitos muy estrictos para las condiciones ambientales. Deben almacenarse en un ambiente con control de temperatura, seco y sin luz solar directa. La temperatura de almacenamiento debe estar entre 18-28℃ (64-82℉), y la humedad relativa debe ser del 40-60%. Los materiales de cera pueden ablandarse o deformarse en un ambiente caluroso, lo que lleva a una reducción en la precisión de impresión. Y los materiales de cera pueden absorber humedad en un ambiente húmedo, afectando la estabilidad de la impresión. Además, los materiales de cera deben mantenerse en recipientes sellados para evitar la entrada de polvo o impurezas. De lo contrario, las boquillas de la impresora pueden bloquearse o la superficie de los productos terminados puede tener defectos. Los materiales de cera deben manejarse con cuidado al moverlos, ya que son frágiles y pueden agrietarse o romperse si se caen o reciben impactos.

Factores a considerar al elegir materiales de cera

Al hacer joyas, los modelos de cera impresos por impresoras 3D de cera se usan para la fundición a la cera perdida. El proceso es: un modelo de cera está rodeado por un material endurecido. Y luego, cuando el modelo de cera se hornea a altas temperaturas, la dureza de la carcasa se fija y el modelo de cera dentro se derrite y vaporiza. Finalmente, la carcasa endurecida se convierte en el molde para el metal fundido. Este proceso requiere materiales de cera de alta calidad.

Enfóquese en tres factores clave al seleccionar cera de terceros:

Contenido de ceniza:

Se deben elegir materiales de cera con bajo contenido de ceniza o sin ceniza para evitar cenizas o residuos dentro del molde después de la combustión. Si se eligen otros materiales de cera, se necesita una limpieza exhaustiva del molde.

Tasa de contracción:

Se debe prestar especial atención al coeficiente de contracción en los datos técnicos. Y se deben elegir materiales con un coeficiente de contracción bajo para minimizar errores dimensionales.

Absorción de agua:

Se debe elegir cera con baja absorción de agua para extender la vida útil de los materiales y modelos de cera.

Preguntas frecuentes (FAQ)

1. ¿Se puede usar la cera roja como material de soporte?

Generalmente, no. La cera roja tiene alta dureza y es difícil de remover, por lo que esto facilita dañar el modelo principal. Por lo tanto, solo es adecuada para imprimir el cuerpo principal del modelo. Generalmente, la cera blanca cumple el papel de soportar estructuras.

2. ¿Cómo se puede evitar el residuo de cera blanca?

En el proceso de eliminar la cera de soporte, es importante controlar estrictamente la temperatura de calentamiento para evitar que la cera roja se ablande. Mientras tanto, usar un disolvente de limpieza compatible y enjuagar a fondo puede reducir efectivamente el residuo de cera blanca. Si queda algún residuo, es necesario usar una lupa o un microscopio para realizar una limpieza secundaria.

3. ¿Cuánto tiempo puede almacenarse un modelo de cera roja?

Generalmente, los modelos de cera roja pueden almacenarse de manera estable durante varios meses o incluso más de un año, si se almacenan en un ambiente con control de temperatura, seco y sin luz solar directa, y los modelos no se manipulan excesivamente. Sin embargo, el almacenamiento prolongado puede resultar en un ligero envejecimiento de la superficie, por lo que se recomienda fundir el modelo de cera lo antes posible.

4. ¿La proporción de cera roja a cera blanca afecta el producto final?

Sí, puede tener cierto impacto. La falta de soporte puede causar que el modelo colapse durante la impresión, mientras que un soporte excesivo aumenta la dificultad de limpieza. Por lo tanto, la proporción de cera roja a cera blanca debe establecerse adecuadamente de acuerdo con la estructura del modelo. Esta es una de las tareas clave para la optimización automática de la mayoría de los software de impresión de cera.

5. ¿Cómo se puede proteger el modelo de cera roja durante la eliminación de la cera blanca?

Se recomienda calentar la cera blanca a baja temperatura o disolverla gradualmente, y evitar un tratamiento de alta temperatura de una sola vez. Mientras tanto, al sacar el modelo de cera, se recomienda usar pinzas suaves o herramientas especializadas para evitar rayar la superficie.

6. ¿Es la cera roja adecuada para todo tipo de diseños de joyería?

Es muy adecuado usar cera roja para hacer estructuras altamente detalladas y complejas. Sin embargo, al producir diseños muy grandes o gruesos, pueden ocurrir riesgos de contracción durante la fundición. En tales casos, es necesario ajustar adecuadamente la estructura del modelo o hacer compensaciones basadas en la experiencia de artesanos expertos.