La impresión 3D en cera resuelve 5 puntos críticos en la fabricación de joyas.

La fabricación tradicional de joyas es un oficio que requiere un esfuerzo inmenso y habilidad manual. Este tipo de método de procesamiento se basa en trabajo manual o semi-manual. Enfrenta problemas como altos costos y capacidad de producción limitada. Hoy en día, el proceso de producción digital de impresión 3D se ha introducido en la industria de fabricación de joyas. Ha proporcionado a la industria de fabricación de joyas un proceso innovador. Este proceso no solo mejora la personalización, sino que también aumenta la eficiencia de la producción. En este artículo, enumeraremos cinco puntos problemáticos comunes en la fabricación de joyas y las ventajas que aporta la tecnología digital de impresión 3D.

Joyería de Oro con Método Antiguo

Puntos Problemáticos del Mercado:

Con el auge del Nuevo Estilo Chino y China-Chic, la búsqueda de calidad y connotación cultural por parte de los consumidores está en constante aumento.

Esto motiva que la Joyería de Oro Antigua disfrute de una mayor aceptación y intención de compra en el mercado. Sin embargo, el proceso tradicional de cera tallada a mano o cera soluble en agua tiene un ciclo largo (normalmente más de 14 días). Su ciclo de proceso prolongado hace que no pueda seguir el ritmo de las últimas tendencias.

Ventajas de la Solución de la Serie WaxJet

Equipado con múltiples cabezales de impresión, una sola impresora 3D puede imprimir aproximadamente 300 patrones de cera para pulseras en 24 horas.

- Desde el inicio del proceso de impresión hasta el despacho del producto final se requieren solo 3 días como mínimo. Esta ventaja hace posible satisfacer idealmente los requisitos urgentes de reposición.

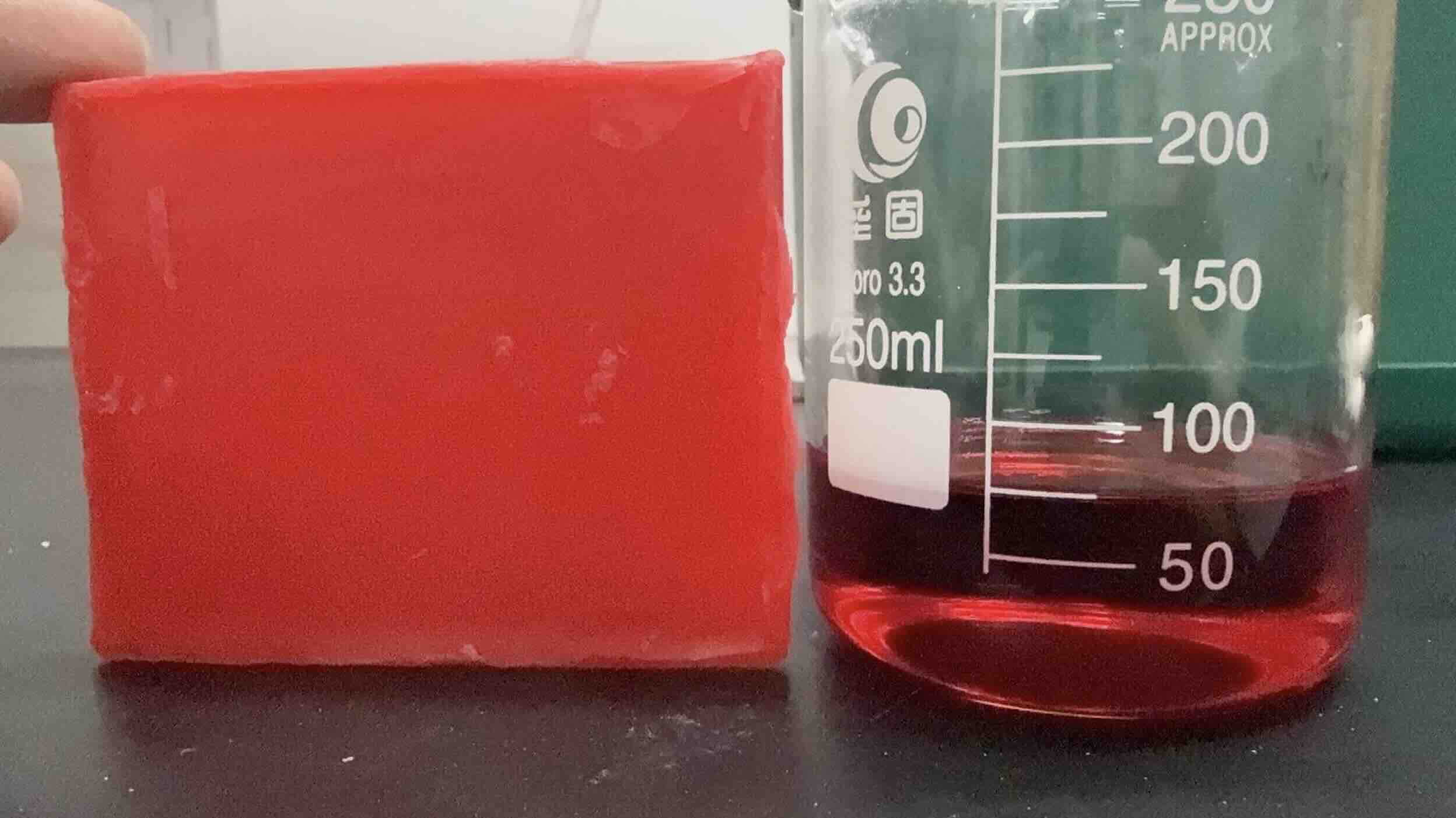

- La cera de soporte soluble en agua única se disuelve de forma autónoma en la solución de inmersión, dejando los patrones calados intrincados completamente intactos.

- La cera estructural especializada ofrece propiedades de fundición idénticas a las de la cera tradicional. Esto garantiza una conexión perfecta con los procesos posteriores y mantiene una calidad constante.

Accesorios Chapados en Oro

Puntos Problemáticos del Mercado:

La ola de compras por transmisión en vivo requiere renovaciones de estilo ultrarrápidas. Sin embargo, los pedidos suelen ser diversos en estilo, pequeños en tamaño de lote y con tiempos de entrega cortos. Pedidos como estos requieren no solo una producción ágil sino también garantizar una calidad constante en cada pieza. Las razones anteriores hacen que sea casi imposible para los modelos de fabricación tradicionales mantenerse al día.

Ventajas de la Solución de la Serie WaxJet

- Una sola impresora 3D puede imprimir de 6,000 a 10,000 patrones de cera de precisión en 24 horas, y es capaz de soportar volúmenes masivos de pedidos a plena capacidad.

- Desde la impresión hasta la entrega de productos terminados se puede completar en 5 días. Esto ayuda a cumplir con plazos de entrega ajustados.

- La tecnología de impresión 3D soporta impresión de alta precisión, que puede restaurar claramente incluso los detalles más pequeños en el borrador de diseño. Esto asegura la calidad estable de cada producto.

- Eliminar la producción de moldes apoya actualizaciones de estilo ultrarrápidas y ayuda a mantenerse al día con las tendencias de transmisión en vivo.

Diseños de Anillos

Diseños de Anillos

Puntos Problemáticos del Mercado:

Los diseños más vendidos suelen ser falsificados tan pronto como salen al mercado. Para diseños planos y con patrones simples, la producción tradicional con moldes prensados es fácilmente replicable. Lo anterior representa una amenaza seria para la seguridad del diseño original y la exclusividad del mercado.

Ventajas de la Solución de la Serie WaxJet

- La tecnología de impresión 3D controla con precisión el grosor de la pared del molde de cera impreso dentro de 0.55 mm. Esto ayuda a eliminar las falsificaciones de alta calidad desde la fuente.

- La tecnología de impresión 3D hace posible imprimir archivos de modelos cifrados bajo demanda y omitir el proceso de molde físico. Con todo el proceso de datos de diseño operando dentro de un sistema de circuito cerrado, podemos mantener nuestros diseños de anillos seguros y protegidos.

- La tecnología de impresión 3D puede completar la impresión de 360 moldes de cera para anillos en solo 24 horas. Esto deja tiempo suficiente para procesos posteriores como fundición y pulido.

Joyería Incrustada

Puntos Problemáticos del Mercado:

La joyería incrustada sigue siendo popular debido a sus diseños diversos y combinaciones de materiales, pero la fuerte demanda impone mayores requisitos en la eficiencia y consistencia de la producción. Las máquinas automáticas de incrustación de cera son varias veces más eficientes que el trabajo manual, pero exigen dimensiones extremadamente estables del patrón de cera y altos estándares de calidad. La fabricación tradicional a mano o la impresión de baja precisión a menudo no cumplen con los requisitos de alta resolución de la joyería fina. Esto se ha convertido en un cuello de botella en las actualizaciones de automatización.

Ventajas de la Solución de la Serie WaxJet

- La tecnología de impresión 3D puede controlar con precisión el tamaño de los moldes de cera y asegurar que el tamaño para el engaste de piedras cumpla con los estándares, logrando así cero compromisos en la calidad del producto terminado.

- Esto desbloquea el potencial de alta velocidad de la automatización y logra una reducción aguda del 30% en los costos laborales.

- La tecnología de impresión 3D ofrece soporte flexible para la impresión personalizada de estilos de incrustación de cera personalizados y allana el camino para la producción en masa de diseños únicos.

Joyería de Oro K

Puntos Problemáticos del Mercado:

Con su brillo único, propiedades amigables con la piel y textura de alta gama, la joyería de oro K sigue siendo la primera opción constante para los consumidores. Sin embargo, el largo ciclo de validación de prototipos, el desperdicio incontrolable de materia prima y el alto costo de prueba y error ralentizan el lanzamiento de nuevos productos. La entrega rápida de la mayoría de los estilos está limitada por procedimientos manuales prolongados y operaciones de mecanizado extensas.

Ventajas de la Solución de la Serie WaxJet

- Imprime prototipos realistas rápidamente. Verifica efectos en tiempo real e itera rápidamente. Acorta enormemente el ciclo de diseño.

- Cambio con un clic, salida directa en lote de patrones de cera de alto brillo. Aplana múltiples pasos tradicionales de fabricación, resultando en un aumento dramático de la eficiencia.

- El nuevo sistema de ultra alta precisión 2900 x 2900 x 1700 dpi asegura un flujo de metal más preciso durante la fundición, reduciendo significativamente el desperdicio de material. Desde la joyería de oro antigua que lleva una historia profunda hasta la ola chapada en oro que barre el mercado, desde la joyería personalizada de oro rosa que protege tu privacidad hasta la joyería de incrustación automatizada, y hasta los diseños personalizados de alta gama que lideran la tendencia en joyería. Los productos de la serie WaxJet están remodelando silenciosamente el panorama de la fabricación de joyas. Es para liberar la artesanía humana, no para reemplazarla, dejando que la artesanía preciosa se concentre en la creación de valor más central.