How to Identify a Jewelry 3D Printer for Detailed Wax Patterns

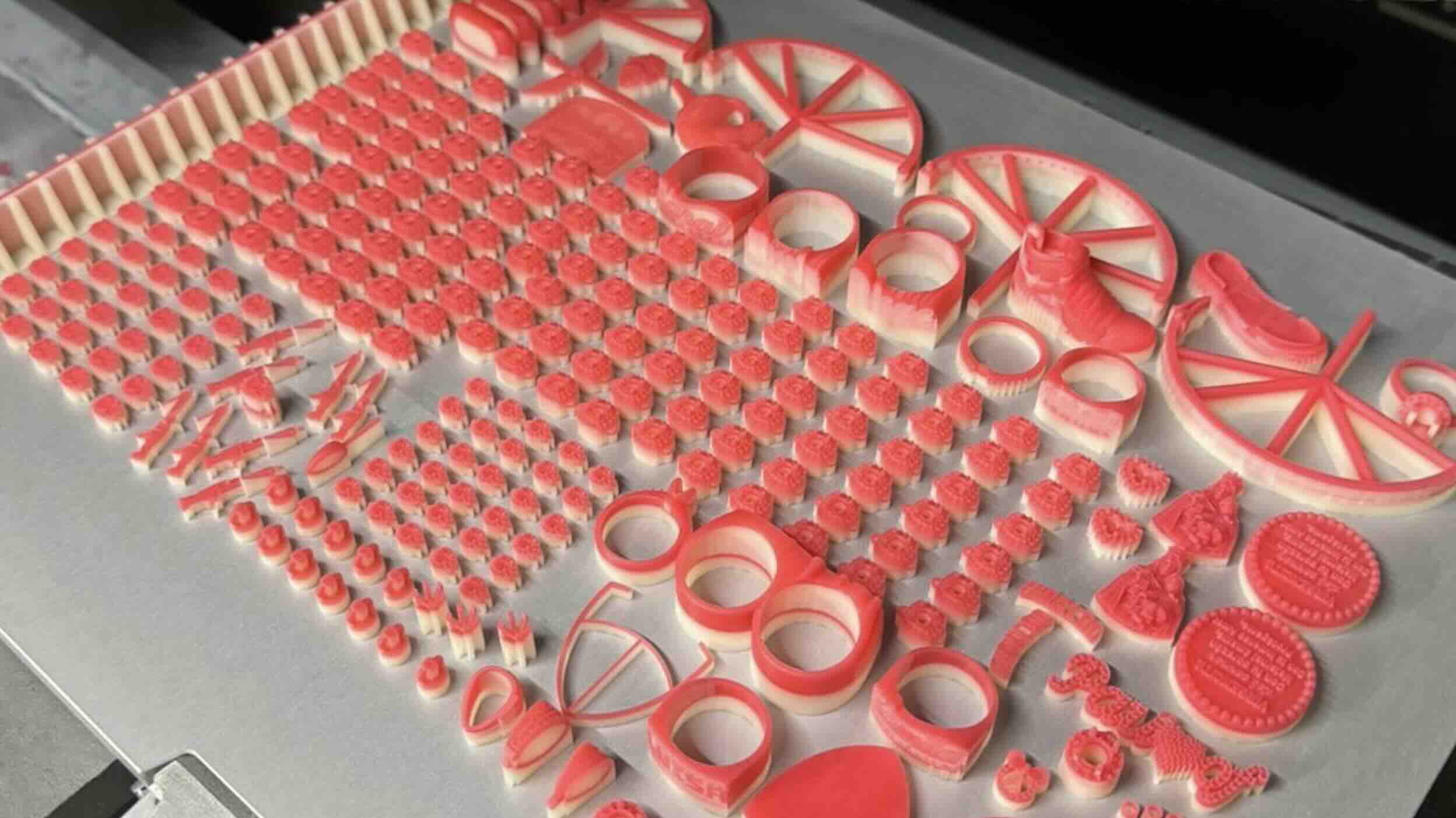

Choosing the right jewelry 3D printer for detailed wax patterns requires more than comparing technical specifications. In waxjet 3D printing, print quality directly affects casting accuracy, surface finish, and production efficiency. This guide explains how to evaluate wax patterns and identify the key performance standards a professional jewelry wax 3D printer must meet.

1. How to Evaluate the Quality of Wax Patterns in Jewelry WaxJet Printing

In jewelry waxjet printing, a wax pattern does not need to merely “look similar” to the design—it must meet strict requirements for accuracy, surface quality, and consistency. A high-quality wax pattern can be evaluated across several critical dimensions.

1.1 Surface Layer Smoothness and Uniformity

Layer lines are an inherent characteristic of waxjet printing. However, high-quality wax patterns should exhibit extremely fine, shallow, and uniform layer lines.

- Evenly distributed layers without visible variation

- Smooth transitions on curved surfaces without rippling

- Minimal visibility to the naked eye, remaining smooth under light magnification

If layer lines are too pronounced, they will be fully transferred to the final metal casting, resulting in rough surfaces and significantly increased polishing and finishing work.

1.2 XY Dimensional Accuracy and Detail Reproduction

Jewelry designs contain numerous micro features, making XY dimensional accuracy one of the most critical factors in evaluating wax pattern quality.

Key aspects to inspect:

- Clarity of micro text and fine textures

- Accuracy of stone seats and prong dimensions

- Sharpness of edges without “softening” or detail loss

Common issues caused by insufficient XY accuracy include:

- Thickened fine lines and closed micro holes

- Slight misalignment in symmetrical structures

- Systematic deviation between the CAD file and printed wax model

Such errors directly impact stone setting precision and the final fit of jewelry pieces.

1.3 Z-Axis Layer Height Control and Vertical Consistency

Z-axis performance determines surface refinement and dimensional consistency along the vertical direction. This is commonly evaluated using a step or staircase test model.

- Clean and well-defined step edges

- Smooth transitions between layer heights

- Absence of periodic banding or vertical artifacts

When Z-axis stability is insufficient, wax patterns may show blurred step edges, surface waviness, or distortion on tall or elongated structures.

1.4 Integrity of Micro Structures and Complex Geometries

Jewelry wax patterns often include thin walls, internal holes, and sharp edges combined with rounded fillets.

A high-quality wax pattern should demonstrate:

- Thin walls that remain intact and undeformed

- Fully formed internal structures

- Accurate reproduction of both sharp and smooth features

The ability to reliably print complex geometries is a key distinction between professional jewelry wax printers and general-purpose equipment.

1.5 Suitability for the Investment Casting Process

Ultimately, wax pattern quality must be evaluated by its performance in casting.

- Ease of handling and removal without damage

- Clean burnout with minimal residue

- Reduction of casting defects and post-casting repair work

A truly high-quality wax pattern performs reliably across printing, casting, and post-processing stages.

2. Performance Standards Required for High-Quality Wax 3D Printing

2.1 Mechanical Precision: Ensuring Dimensional Accuracy

Mechanical precision forms the foundation of wax pattern quality and determines whether printed dimensions faithfully match the CAD design.

Z-Axis Layer Thickness Standards

- General-level equipment: Minimum layer thickness of 25–30 microns, with visible layer lines and noticeable stair-stepping on curved surfaces. Suitable for simple designs but limited for fine jewelry.

- High-precision jewelry wax printers: Minimum layer thickness of 15 microns or lower, producing extremely smooth surfaces with minimal visible layering, ideal for high-end and intricate jewelry designs.

XY Resolution Standards (DPI-Based)

- General-level printers: XY resolution around 500–600 DPI, where fine lines and micro holes may lose definition and small text appears blurred.

- Jewelry-grade wax printers: XY resolution of 800–1000 DPI or higher, enabling clear micro text, precise stone seats, and sharp edges.

In jewelry manufacturing, even small dimensional deviations can compromise stone setting and assembly accuracy. Therefore, mechanical stability and precision are essential baseline capabilities.

2.2 Consistency and Repeatability in Production

Excellent single-print results are not sufficient for professional jewelry production. Consistency and repeatability are equally critical.

- Printing the same model multiple times to verify consistency

- Assessing uniformity across batch production

- Monitoring quality stability during extended operation

In real-world jewelry manufacturing, repeatability directly affects yield rates, labor efficiency, and production reliability.

3. Frequently Asked Questions (FAQ)

Q1: What resolution is considered sufficient for jewelry wax 3D printing?

A: Jewelry wax patterns typically require an XY resolution of at least 800–1000 DPI and a Z-axis layer thickness of 15–25 microns to achieve fine detail and smooth surfaces.

Q2: Is higher DPI always better for wax pattern quality?

A: Not necessarily. While higher DPI allows finer detail, actual print quality also depends on mechanical precision, wax droplet control, and software algorithms.

Q3: Can DLP resin printers replace wax 3D printers for jewelry casting?

A: DLP printers can use castable resins, but dedicated wax 3D printers usually offer superior surface quality, cleaner burnout, and higher reliability for investment casting.

Q4: Why is repeatability important in jewelry wax 3D printing?

A: Consistent repeatability ensures dimensional accuracy across batches, which is essential for stone setting, assembly, and reducing rework.

Q5: Are machine specifications alone enough to judge a wax 3D printer?

A: No. Real-world test results, sample prints, and long-term consistency are far more reliable indicators than specifications alone.