How are rings made from 3d models by wax 3d printer

Digital Transformation in Jewelry Production

For millennia, lost-wax casting has been the cornerstone of precious metal jewelry fabrication. Traditional methods demanded master artisans to hand-carve wax models—a time-intensive process (3–8 hours per piece) prone to human error and design limitations. Modern 3D printing disrupts this legacy with:

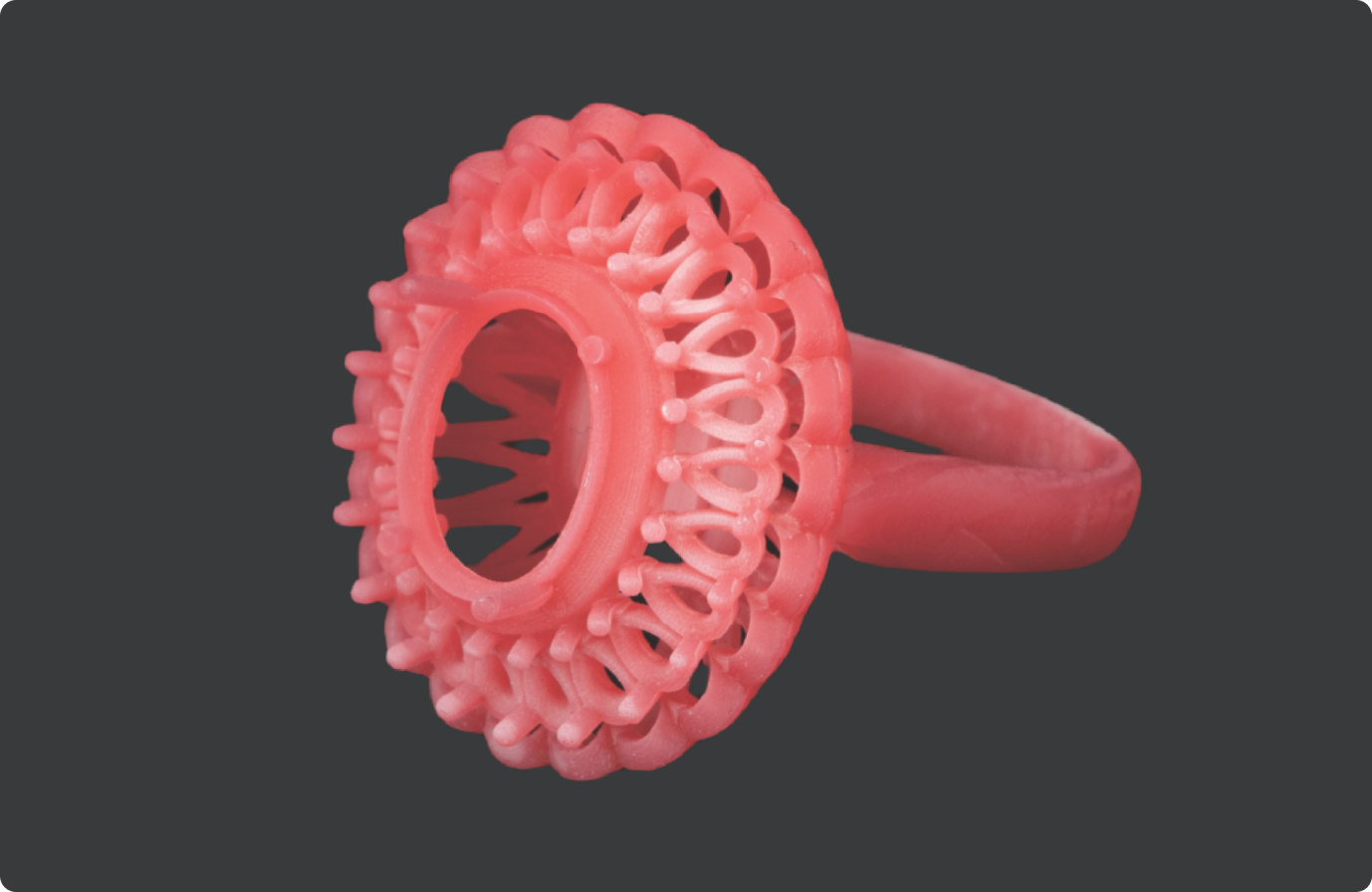

Precision: Industrial printers like the Flashforge WaxJet 530 achieve ±0.04mm accuracy and 15-micron layer resolution (1/5 human hair width), capturing intricate details like micro-prongs and lattice textures.

Efficiency: Produce 9,000+ rings monthly per machine with 24/7 automated operation.

Design Freedom: Rhino, Matrix, or ZBrush software enables complex geometries, rapid iteration, and trend-responsive customization.

|

Comparison |

Hand Carving |

3D-Printed Wax |

|

Time per Ring |

3–8 hours |

0.5-2 hours |

|

Dimensional Accuracy |

±0.2mm |

±0.04mm |

|

Complex Geometry |

Limited |

Unlimited |

|

Monthly Output (Rings) |

~300 |

~9000 |

|

Labor Dependency |

Master Artisan |

Automated System |

The Modern 8-Step Workflow:

1. 3D Model Design → 2. Slicing & Data Prep → 3. Wax Model Printing → 4. Support Dissolution

→ 5. Investment Mold Creation → 6. High-Temperature Burnout → 7. Metal Casting → 8. Polishing & Finishing

Detail of Wax Model Printing and Gold Casting

Step 1: 3D Rings Model Design

Software for Precision Jewelry Modeling:

Professional 3D design tools like JewelCAD, Blender, and RhinoGold empower designers to create intricate, customizable jewelry models with unmatched accuracy—unlocking the full potential of 3D-printed wax casting.

Key Advantages of Digital Jewelry Design:

Parametric Customization – Adjust ring sizes, prong positions, and pattern density with pixel-perfect precision, eliminating hand-drawing inaccuracies.

Automatic Overhang Detection – AI-powered tools identify unsupported structures and optimize print angles for flawless wax model production.

Real-Time Photorealistic Rendering – Simulate lighting and materials to visualize the final product before printing, reducing costly physical prototypes.

Seamless Personalization – Integrate custom engravings, fingerprints, or unique textures directly into the 3D model for one-click bespoke jewelry creation.

Step 2: Model Slicing - Optimizing 3D Jewelry Printing for Precision Results

Flashforge WaxJetPrint software represents the all-in-one slicing software, transforming 3D jewelry designs into perfectly optimized printing instructions for flawless wax model production. This intelligent solution combines automated analysis with manual editing capabilities, delivering unprecedented control over every aspect of your jewelry prints.

Ultra-Precise Layer Settings

Achieve jewelry-grade perfection with adjustable layer heights (0.025-0.05mm), meticulously balancing exceptional detail resolution with optimal print speeds for production efficiency.

Intelligent Support Structures

Our advanced algorithm automatically creates optimized support structures for even the most complex designs, utilizing soluble wax materials that dissolve cleanly without compromising delicate pave settings or intricate openwork patterns.

Powerful AI stacking and layout ability

The industry's most intelligent stacking system employs deep learning algorithms to maximize build plate utilization with smart model arrangement, reduce printing time through optimized 3D stacking, and continuously improve efficiency via machine learning iterations.

Step 3: One-Click 3D Printing Process

The sliced file is imported into an industrial-grade wax 3D printer such as the WaxJet 530, where advanced piezoelectric printheads precisely jet micro-droplets of molten wax onto the build platform, gradually constructing the model layer by layer with exceptional accuracy. This automated printing process delivers several critical technological advantages for jewelry manufacturing:

The system enables multi-material printing, utilizing high-hardness casting wax for the model structure while employing water-soluble or low-melting-point wax for support structures, ensuring easy separation without damaging delicate design elements.

With its generous build volume of 289×208×100mm, the printer can simultaneously arrange and produce dozens of ring models in a single batch, maximizing production efficiency while maintaining consistent quality across all pieces. This combination of precision engineering and scalable production capacity makes modern wax 3D printing ideal for both custom jewelry pieces and larger production runs.

The entire operation can be initiated with a single click, transforming digital designs into physical wax models with minimal user intervention while maintaining the high standards required for professional jewelry casting applications.

Step 4: Support Removal Through Solution Cleaning

After the printing process is complete, the wax models undergo a thorough cleaning procedure to remove all support structures. The printed pieces are immersed in specialized wax-cleaning solutions, such as bio-based solvents or isopropyl alcohol, where they remain submerged for 10-15 minutes. During this time, ultrasonic cleaning equipment generates high-frequency vibrations that accelerate the dissolution process, ensuring complete removal of even the most intricate support structures. Following the ultrasonic treatment, technicians gently brush the models with soft-bristle brushes to eliminate any remaining residue, paying particular attention to delicate areas and fine details.

This two-stage cleaning process guarantees that the final wax models emerge completely clean and free of support material remnants, preparing them perfectly for the subsequent investment casting phase while preserving all the precise details of the original design.

Step 5: Investment Mold Creation - Preparing for Precision Casting

The wax models are carefully assembled into a "wax tree" structure by attaching multiple pieces to a central wax sprue using specialized jewelry welding techniques. This cluster configuration maximizes production efficiency by enabling batch casting of numerous pieces simultaneously.

The prepared wax tree is then secured inside a steel flask, where liquid investment plaster (formulated specifically for jewelry applications) is poured to completely encapsulate the models. A vacuum chamber removes all air bubbles from the mixture, ensuring defect-free mold surfaces that will capture every intricate detail of the original wax patterns.

The investment material undergoes a controlled 4-6 hour curing process at room temperature, gradually transforming into an ultra-durable refractory mold capable of withstanding extreme casting temperatures. This critical phase creates the perfect negative impression of your jewelry designs, ready for the molten metal pouring process.

Step 6: Wax Burnout & High-Temperature Firing

The investment molds undergo a critical firing process in specialized burnout ovens at 850°C for 6-8 hours. This high-temperature treatment completely eliminates wax residues while transforming the plaster into an ultra-strong refractory mold capable of withstanding molten metal injection during casting. The resulting hollow cavity precisely preserves every detail of the original 3D design for perfect metal reproduction.

Step 7: Metal Casting – The Transformation Process

Gold or precious metals are melted at 1064°C in induction furnaces, then injected into the ceramic mold under centrifugal force to capture every detail. After cooling, the mold is broken away to reveal perfect metal replicas of the original wax designs, ready for finishing.

Step 8: Professional Polishing & Quality Assurance

The final stage transforms raw castings into dazzling jewelry pieces through meticulous hand-finishing. Artisans first remove sprues and casting marks using precision files and rotary tools, then progress through graduated polishing (600-3000 grit sanding) before achieving mirror finishes with magnetic polishing systems and diamond compounds. Each piece undergoes rigorous quality control under magnification to verify:

• Prong alignment accuracy

• Perfect ring circularity

• Flawless surface finish

Industry Transformation - How 3D Printing is Revolutionizing Jewelry Manufacturing

The advent of 3D printing technology has fundamentally reshaped the jewelry industry landscape, creating unprecedented opportunities for brands and consumers alike. By enabling true digital manufacturing, this innovation has made mass customization the new standard - customers can now submit personalized designs online and receive one-of-a-kind pieces through on-demand 3D printing production.

The technology's rapid prototyping capabilities have compressed traditional development cycles, allowing designers to transform concepts into physical samples within just 2-3 days. This accelerated timeline gives brands a crucial competitive edge in bringing trend-responsive collections to market faster than ever before.

Perhaps most significantly, 3D printing's automation has slashed production costs by over 70% compared to traditional methods. By eliminating labor-intensive hand-carving and reducing material waste, the technology has democratized high-end jewelry production - empowering independent designers and small studios to compete in the premium customization market previously dominated by major houses.

Industrial-Grade Solution – Flashforge Waxjet 530 3D Printer

The Flashforge Waxjet 530 represents the pinnacle of professional 3D printing technology for jewelry manufacturing, combining exceptional precision with remarkable production efficiency. This industrial-grade wax 3D printer delivers unparalleled performance for both small-batch custom pieces and high-volume production runs, making it the ideal choice for modern jewelry makers.

Engineered for reliability, the Waxjet 530 features an advanced triple-printhead system that ensures stable, uninterrupted operation with impressive yield rates of 58-60%. Its generous build volume accommodates multiple wax patterns simultaneously, while maintaining consistent micron-level accuracy throughout every print job.

The integrated real-time monitoring system, complete with built-in camera, allows technicians to oversee the entire printing process remotely. This smart feature enables immediate quality control and peace of mind during extended production cycles.