Der Leitfaden zu 3D-Silberdruckern für maßgeschneiderten Schmuck

Was ist ein 3D-Silberdrucker?

Da die Schmuckindustrie schnell in Richtung Digitalisierung und Personalisierung voranschreitet, ist der 3D-Silberdrucker zu einer Kerntechnologie für Designer, Schmuckstudios und Marken geworden. Er verändert nicht nur die Art und Weise, wie Silberschmuck entworfen wird, sondern senkt auch erheblich die Hürden für die Herstellung von maßgeschneidertem Schmuck. Dies ermöglicht es mehr Endverbrauchern und Unternehmern, an der Herstellung personalisierter Stücke teilzunehmen.

Bei der ersten Suche nach einem 3D-Silberdrucker haben viele Menschen Fragen:

- Kann Silberschmuck wirklich direkt „gedruckt“ werden?

- Auf welche Art von Geräten bezieht sich der Begriff „3D-Silberdrucker“ auf dem Markt?

- Welche Technologie ist besser für die kommerzielle Produktion im Vergleich zur persönlichen Anpassung?

Dieser Artikel bietet eine umfassende Analyse des 3D-Silberdrucks aus drei wichtigen Perspektiven: technische Prinzipien, Materialanwendungen und typische Anwendungsfälle, um Ihnen ein tiefgehendes Verständnis dieser innovativen Technologie zu vermitteln.

Was bedeutet „3D-Silberdrucker“ eigentlich?

Streng genommen drucken die meisten derzeit als 3D-Silberdrucker vermarkteten Geräte keine fertigen Silbermetallobjekte direkt. In der Schmuckindustrie bezieht sich dieses Konzept hauptsächlich auf Drucker, die zur Herstellung von Modellen oder Wachsformen für das Silbergießen verwendet werden. Mit anderen Worten, 3D-Druck ist ein entscheidender Schritt in der Produktionskette von Silberschmuck, nicht die Methode zur direkten Ausgabe des Endprodukts.

3D-Wachsmodell-Druck + Feingussverfahren (Die Mainstream-Methode)

Dies ist derzeit die ausgereifteste und am weitesten verbreitete Methode für den 3D-Silberdruck in der Schmuckindustrie.

Ablauf:

- Druck eines hochpräzisen Wachsmodells oder eines gießbaren Harzmodells mit einem spezialisierten 3D-Drucker.

- Einbetten des Modells in ein hitzebeständiges Material (wie Keramik oder Gips), um eine Gussform zu bilden.

- Ausbrennen des Wachsmodells bei hoher Hitze, wodurch eine hohle Kavität entsteht.

- Einfüllen von geschmolzenem Silber (wie 925 Sterlingsilber oder anderen Legierungen) in die Kavität.

- Nach dem Abkühlen wird die Form entfernt und mit Nachbearbeitungsschritten wie Polieren, Strahlen und Steinfassung fortgefahren.

Wichtige Vorteile:

- Fähig, extrem feine Details, Texturen und Mikro-Pavé-Strukturen zu erzeugen.

- Ausgereifter, zuverlässiger Prozess mit hoher Erfolgsquote.

- Kostengünstiger als direkter Metalldruck, geeignet für die meisten Studios.

- Sehr kompatibel mit traditionellen Gussverfahren.

Anwendungsbeispiele:

- Individuelle Eheringe: Ermöglicht die Integration von Fingerabdrücken, Handschriften oder Namen des Kunden.

- Komplexe künstlerische Ringe: Aufwändige Gravuren von Ranken, Tieren oder abstrakten Texturen.

- Kleinserien-Aufträge: Bietet eine kostengünstige Produktionslösung für E-Commerce-Plattformen und Schmuck-Startups.

Gängige Materialien für den 3D-Silberschmuckdruck

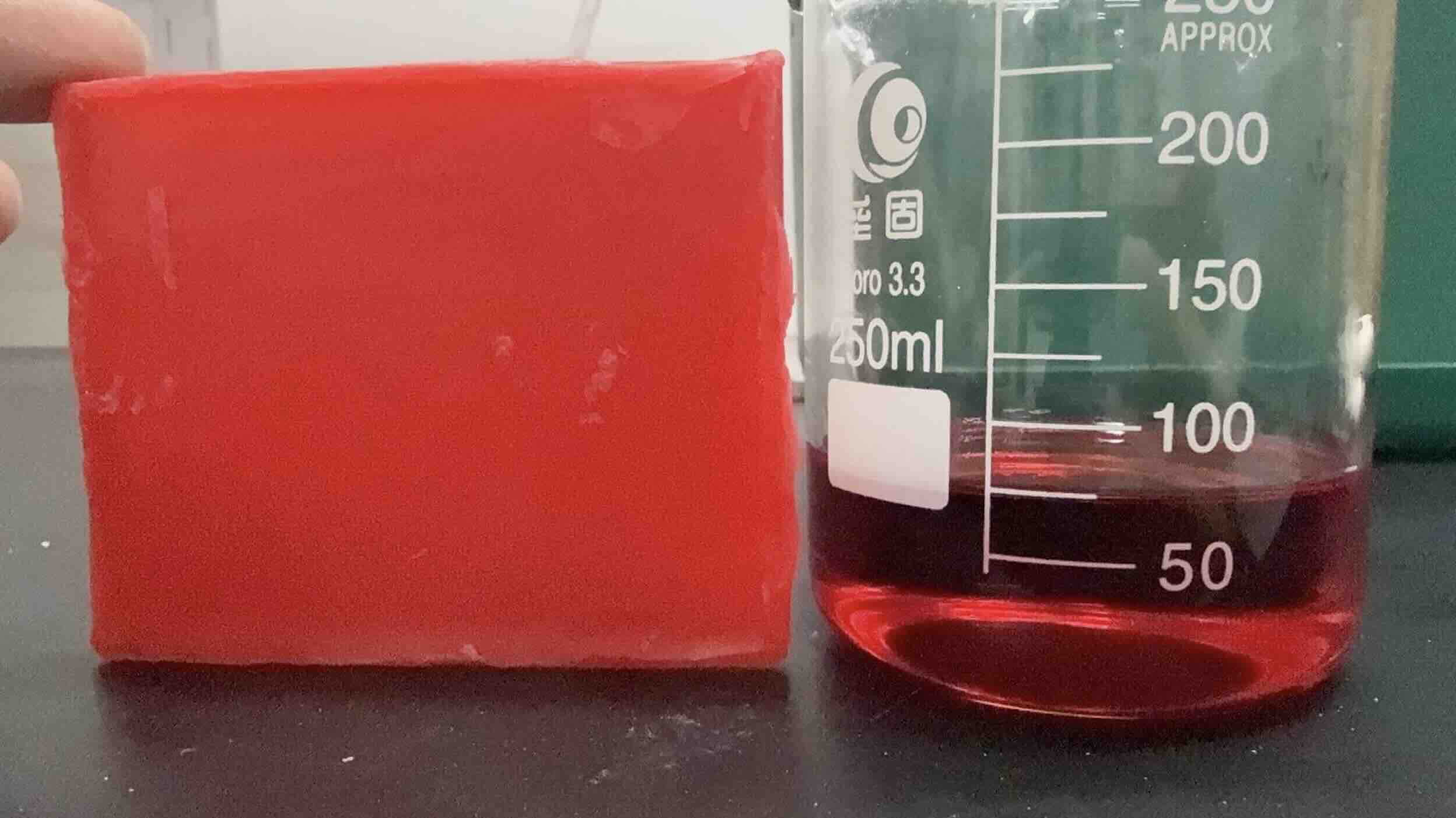

Wachs / Gießbares Harz (Das Kernmaterial für den Druck)

- Ermöglicht hochauflösenden Druck mit feinen Details.

- Erzeugt eine glatte Oberflächenbeschaffenheit, ideal für Pavé-Fassungen.

- Verbrennt sauber mit minimalen Rückständen.

- Perfekt kompatibel mit dem Gießen von 925 Silber und anderen Silberlegierungen.

Dieses Material bildet die Grundlage des 3D-Silberdrucks und ist die wichtigste Wahl für die meisten Designer.

Silberlegierungen (Für die Gussphase)

- Häufig verwendet: 925 Sterlingsilber.

- Bietet nach dem Polieren ein helles, glänzendes Finish.

- Stabil, langlebig und für den täglichen Gebrauch geeignet.

- Kann mit verschiedenen Karat-Goldlegierungen für unterschiedliche Farbeffekte kombiniert werden.

Anwendungsszenarien für 3D-Silberdrucker im Schmuckbereich

Mit der Verbreitung des 3D-Drucks ist die Herstellung von Silberschmuck flexibler und vielfältiger geworden.

- Individuelle Ringe: Personalisierte Gravuren, Größenanpassungen und einzigartige Formen.

- Eheringe / Versprechensringe: Ermöglicht den Druck detaillierter Texturen und kreativer Designs.

- Künstlerischer Silberschmuck: Komplexe Muster, Tiermotive und skulpturale Stile.

- Silberkunst & Handwerk: Künstlerische Skulpturen und kreative Ausstellungsstücke.

- Kleinserienproduktion: Erfüllt die Bedürfnisse von E-Commerce und personalisierter Nachfrage.

- Schmuckprototypen: Schnelle Designvalidierung, spart Formkosten.

Im Vergleich zur traditionellen handgeschnitzten Wachsmodellierung ermöglicht der 3D-Druck eine schnellere Umsetzung von Designs, höhere Replikationsgenauigkeit und verbesserte Produktionseffizienz für Silberschmuck.